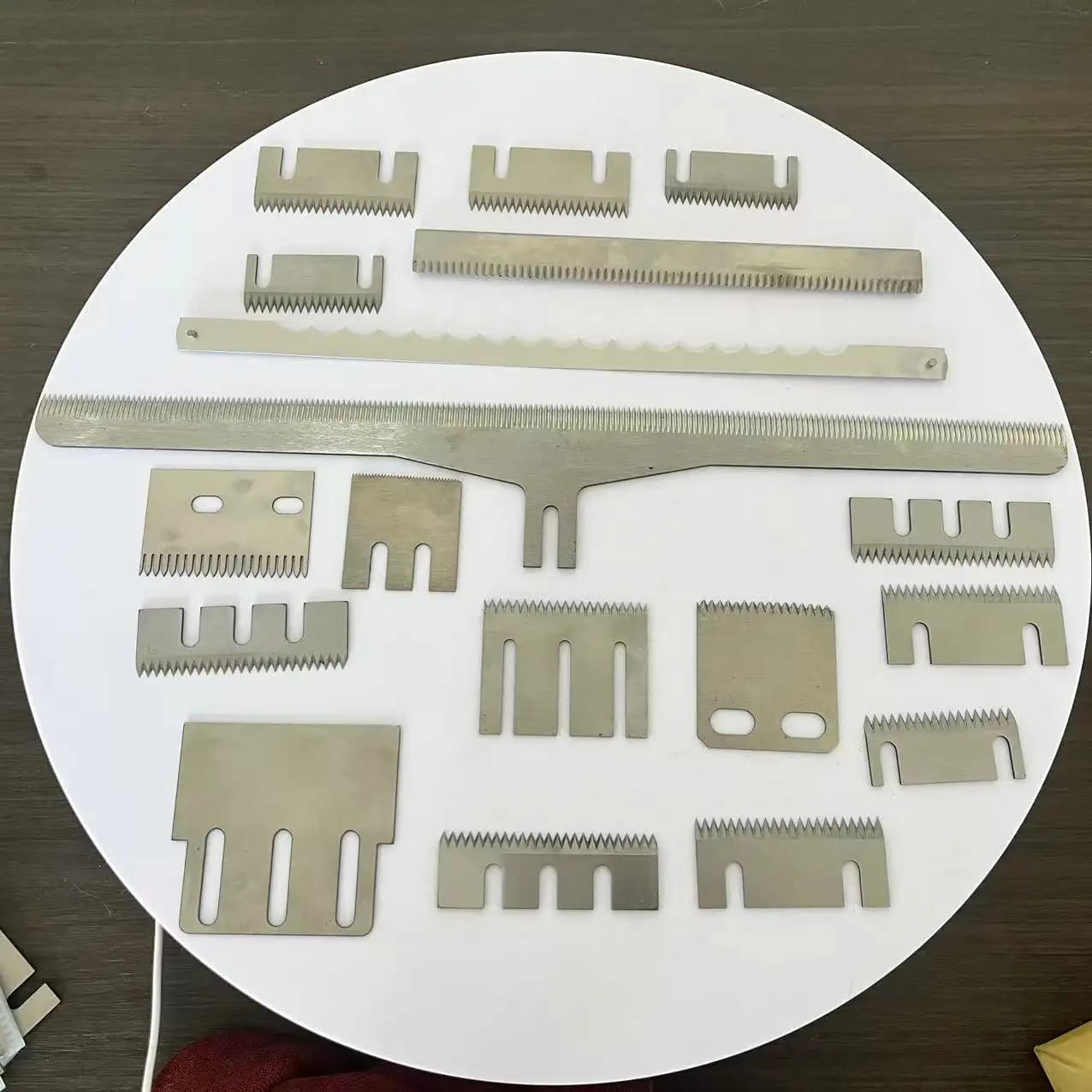

plastic crushing blade

The plastic crushing blade is an essential component in the waste plastic recycling industry. Its main function is to effectively crush and grind plastic materials into smaller, more manageable sizes. These blades are technologically advanced, featuring high-quality steel construction and a unique cutting edge design that ensures durability and efficiency. With excellent wear resistance and the ability to handle high volumes of plastic, these blades are integral to the operation of plastic granulators. Applications of the plastic crushing blade extend to various industries, including manufacturing, packaging, and waste management, where they play a crucial role in reducing plastic waste and enabling recycling.