Introduction

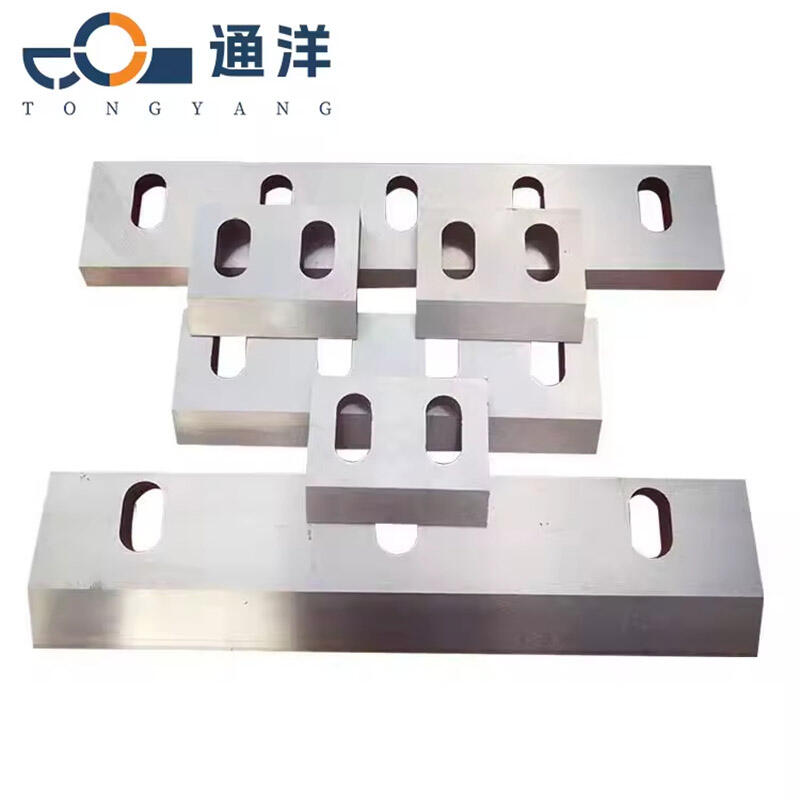

Crusher blades are used by the grain size development and material processing industries, in this world. These blades are used as the major components in different crushing machines which include construction, mining, recycling industries etc. The type of blade applied also greatly determines how efficient and effective the crushing process is going to be. Here, we will be discussing the most common types of crusher blades used in this world and some outlines about crusher blade which non-reversible blades for specific materials, reversible type with sharp edges for all purpose, and methodological advancements to manufacture a new class of Crusher Blade through CNC technology.

Jaw Crusher Blades

NWRD Stationary Equipment Jaw crushers are one of the common types of crushers. Its mode of operation is through the two jaws, one jaw is fixed while the other jaw moves in a slow periodic motion to crush material. Blades used in jaw crushers are typically referred to as moving (swing) and fixed blades.

Reciprocating Jaw Blades: Reciprocating jaws crush material against the opposition manual jaw. They are created to resist wear and high impaction, making it essential for the crushing process.

Fixed Jaw Blades: the fixed blade crushes the material to be processed, providing a flat surface onto which undulating jaws crush. They are often built with high-manganese steel to strengthen the wearability.

Jaw crushers are often used for crushing hard materials such as granite, limestone and concrete in construction and demolition plants.

Cone Crusher Blades

Cone Crushers Cone crushers are also a type of crusher that is widely used in secondary and tertiary crushing applications. The cone machines crushes materials via the mantle and the concave liners or the conical blade.

Manganese: Manganese steel has a high toughness, good manufacturability and low price.it is widely used in the fields of building materials, mineral processing, chemical industry and other industrial sectors.

Blades in High Chrome Steels Cones: they have great wear resistance for this reason it is excellent for them to perform the crushing of abrasive materials.

Roll Crusher Blades

Roll crushers use two or more cylinders or drums which are connected to horizontal shafts, and crush the materials by pulling them. In teeth roll crusher, the gear roller blades are types of.fixed gap adjusting modes for the gear.

Smooth Rolls: They are used for crushing soft materials and produces a uniform product size.

Toothed Rolls are heavy duty blades with sharp teeth, used for higher impact applications.

Roll crushers are often used in the coal, cement and mining industries to reduce material handling ( bottom left).

Gyratory Crusher Blades

Gyratory crushers that are designed to handle millions of tons per year are used for high-throughput operations. Blades in gyratory crushers include —

Spider Caps: Protect the top of the crusher and aid in material flow.

Mantle and Concave Liners — The mantle is a movable piece that is securely fixed around the main shaft, thus enabling crushing materials to be obtained between the mantle and concave.

Typically a large mining outfit would opt to go for a gyratory crusher since it can give you more output capacity and also comes with good energy efficiency.

Shear Crusher Blades

Shear crushers, including those that cut and shear materials as opposed to the crush result. The blades of shear crushers can be;

Straight Blades: These blades are for shearing in general.

Curved Blades: providing better cutting results for some specific materials these blades are used in certain cutting tasks.

This type of primary crushing is typically done using shear crushers or "breakers" for recycling; plate steel Shear Breaker".

Hammer Mill Crusher Blades

What are Hammer mills Hammer mills are versatile machines for material size reduction. Hammer mill blades can differ :

Flat-Faced Hammers: If all you need grinding for is general-purpose use, these hammers are for you.

Black Sickle Shaped Hammers: The ideal blades for specific uses that allow better cutting efficiency.

Hammer mills are a popular choice in agriculture, food processing, and waste management across the United States because of their ability to process many materials.

Crusher Blades Types Comparison Only

Crusher Blade Selection When considering the crusher blade selection, there are several factors as material type and particle size for the objects being cut along with specific application requirements. This is because different blades have their own features which are somewhat more specific to the intended work. Jaw crusher blades are suitable for hard materials such as granite, while impact curls are free and even-yet better suited to soft conditions that are more abrasive.

Conclusion

Crusher blades and their uses Knowing the different types of crusher blades for shredders is essential when trying to maximize crushing operations. Blade types Each blade type is meant for a specific application, capable of cutting through different kinds of materials. The right crusher blade can not merely improve the working efficiency for any crushing machine but also might prolong its lifespan.