Introduction

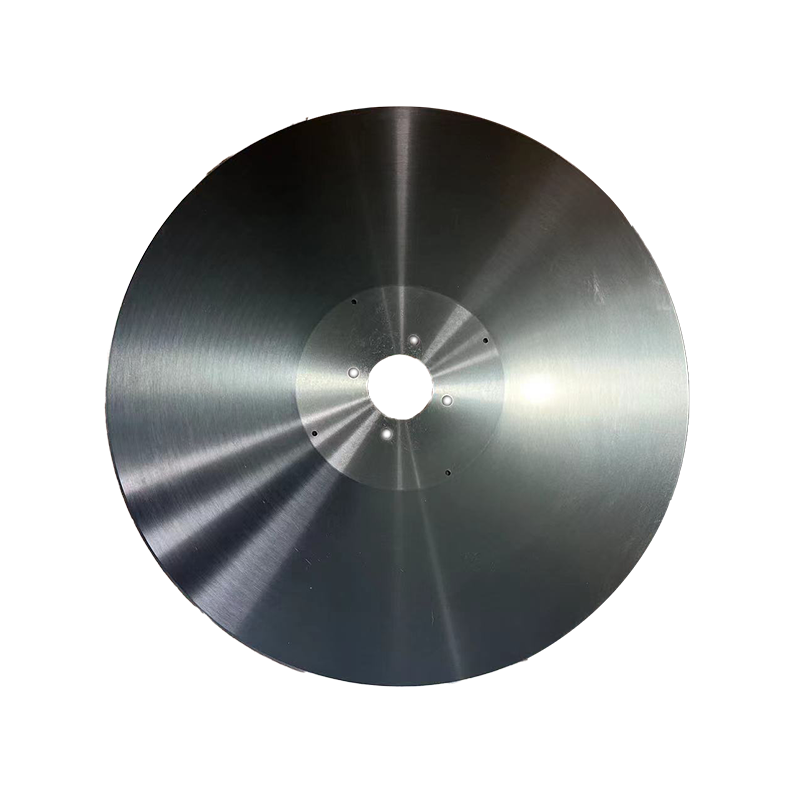

This is especially true for the blade of a machine. Improperly mounted Circular Blade can result to bad cutting service, lesser life of machine and possible safety issues. And this is why when mounting a circular blade to your cutting machine, it's best to do it the right way. This guide runs you through everything from pre-mounting inspection to post-mounting checks and safety.

Pre-Mounting Inspection

You need to check the blade and the machine for any possible problems prior to starting the process of mounting. If the blade shows any signs of damage such as chipping or cracking, you might want to check if it is indeed still safe to use. Just make sure to check that the blade diameter and arbor hole size match your specific machine. Further inspect for clean, damage and missing arbor and spindle of the machine that help to keep the blade in place, without a blade retaining;blade will not cut properly)||

Machine Preparation

You must always remember…your safety first. Do this with the cutting machine turned off and unplugged. Check for any existing blades or attachments and remove them. The arbor and spindle of the machine should be correctly aligned Configure Services. Improper alignment can cause an inconsistent wear on blades and decreases the overall cutting performance.

Blade Preparation

Wipe the blade with a clean cloth to remove any dirt or debris that can interfere in its spinning and calibration. Confirm which way the blade spins so it's compatible with your machine. The arrow points to the correct rotation for most blades. Also ensure you are setting in properly (see above) for the needed flat side on your blade to fit into the arbor.

Mounting the Blade

Position the blade on the machine arbor with the correct side facing up Keep the selected length of hole in line with machine spindle The blade should be flat and sitting straight with zero wobble. If necessary, fasten the blade with an appropriate nut and a washer. Make sure the blade is centered on the arbor and spindle or it will wear unevenly over time and may potentially become unbalanced.

Tightening the Blade

The amount of torque you put into the tightening now affects how loose or tight that blade is gonna be. Slowly secure the nut using a torque wrench to the proper manufacturer-specified spec. Too much tension will grind that blade down or snap it under the load. Under tightening can also be harmful, because the blade may come loose while it is being used.

Post-Mounting Checks

Once you get the blade mounted then the next step is to do a series of checks as usual, making sure everything is okay. Turn the blade by hand to see if it spins exactly and without vibration. Next, we need to make sure that the blade is not loose and firmly secured. Also inspect the guard to machine contact, with a blade this could cause accidents or damage on operation.

Test Run

After the checklist, you are good to go so: RUN! Turn the machine on low and listen to feel for any out of the ordinary noise/ blade not humming evenly. Commonly this poor sawing performance appears through cuts that do not go anywhere close to straight or are wavy and line up with no definition, both of which could be indication that the blade is mounted incorrectly or other problems that require attention. Again, test run the sae to determine if blade tension is correct and adjust again as needed.

Safety Precautions

Safety First — During the mounting process, it's important to always wear proper safety gear, like eye protection since any debris could potentially cause damage. Make sure all guards and safety features are in place before starting the machine. Take care and follow the safe alternations to avoid accidents, refer to their official site for proper information.

Maintenance and Storage

Preserving and storing your knife is as critical as the mounting itself. After each use, clean and re-oil the blade to guard it against rusting. Should be kept in a safe place without being use. so that blade doesn't gets damaged. Check the blade regularly for wear or damage and replace it as needed.

Conclusion

Properly installing a round-blade in your cutting machine is critical to the overall cutting performance, long-lasting of the machine life and safety. From pre-mounting inspection and machine and blade preparation, to mounting, tightening, post-mounting checks, a test run, and observing recommended safety measures...

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

KA

KA

UR

UR

BN

BN