Introduction

In the mining and Rotary crusher industries, crushers are integral components used in breaking down run-of-mine material to nominal sizes my means of compressing rock between two rigid surfaces. Thus the blades longevity is one of the very important parameters that significantly affect crushing efficiency and cost effectiveness. Machine operators must consider what factors affect the lifespan of crusher blades to help optimize their efficiency and reduce downtime. In this article you will learn why and how the crusher blade life can be increased, covering factors that affect the durability of crushing blades from their material reports to maintenance practices.

Material Composition

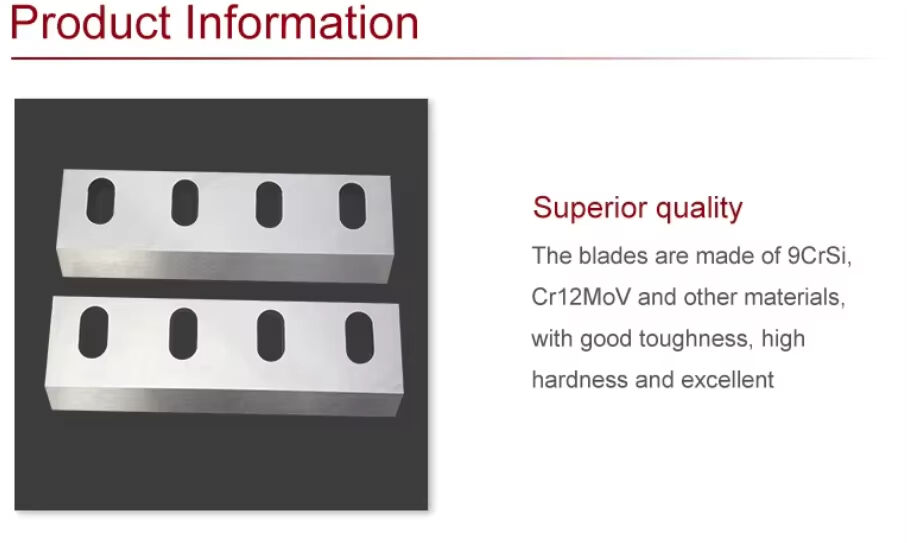

Perhaps the most important element influencing the lifespan of crusher blades is the material used to construct them. Because there are different materials to choose from, some come with the various properties of how long the blades will last.

High carbon steel is wear resistant but may not offer enough toughness.

• Alloy steel is known for their combination of hardness, strength and wear-resistance to meet the requirements of many application.

• This method is applicable high manganese steel can withstand impact and wear resistant features, its excellent work ability, and ideal crushing of hard, abrasive materials.

• Ceramic materials are highly effective in resisting wear, but they can be brittle and have a risk of impact-related damage.

The selected material is chosen according to the application requirements of the target crushed material as a result of these functions.

Design Factors

Role of Crusher Blades Design in its Life Span From the blade geometry to tooth design, and from the fixations of blades all combine to determine how long will that blade last.

Blade life: Proper blade geometry will ensure that the blades wear evenly and prevent premature failure, adding more years to the life of your blade.

Tooth Pattern and Shape These factors can influence the rate of movement on crushing materials, and how quickly blades need to be replaced.

The blades need to be tightly kept together during operation to avoid accelerated gear wear or worse destroy the transmission from loss of blade hard-shearing effects.

Operating Conditions

Crusher blades also have a useful life based on the operational conditions of environment of how and for what it is being utilized. The size of feed material, crusher settings, and the composition of rock all contribute to inexplicable blade wear

Feeding greater than specified sizes or more abrasive feed material will result in excessive wear of the blades.

Setting a jaw too tight to allow it in advance of the most expensive wear part-steel, steel being the easiest target for stoppage in Kidney Crusher as written.

The quality and service life of crusher blades are directly related to the economic interests of users, in addition to mechanical use and many other aspects.

Maintenance Practices

Crusher Blade Extending Maintenance Plugin Frequent checks may be able to spot wear or damage that could results in premature failure.

– Need to minimize friction and the level of heat generated, that would help avoid wear -Lubrication

– The blades will last longer without getting damaged if you stuff the machines properly and ensure a constant rate of feed.

Performing preventive maintenance such as regular inspections and timely appliance of worn components will help to retain the blades in top-notch condition.

Usage Patterns

The way these blades are use can also impact the longevity of crusher blades. Blade life also can be shortened with overloading, processing abrasive materials or inconsistent feed rates.

Operator skill and experience: Crusher blades have a relatively long lifespan, but an unskilled operator can easily wear them out or damage them.

How often you use your blade Prolonged use may cause your blades to wear faster than periodic use.

Manufacturing Quality

Production process is good or bad, and to a great extent determine the service life of crusher knife. That high-level manufacturing is expected of a top launch, and it means these blades will be free from the more egregious defect that might lead to premature failure.

The manufacturing process, which includes hardness, and toughness in the blades of the rollers during heat moulding or welding operations.

- Blades are manufactured according to the desired specifications and standards with inspections and testing for quality control.

- Selecting established manufacturers and suppliers will result in a higher-quality of blades.

Conclusion

Factors affecting the service life of crusher blades are complex but include the material composition, design and working conditions as well as maintenance. With the above in mind operators can select appropriate crusher blades and use them to ensure best performance from their crushers as well as an overall longer life of the blade, all with the intention of maintaining efficient crushing operations.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

KA

KA

UR

UR

BN

BN