pneumatic knife holder accessories

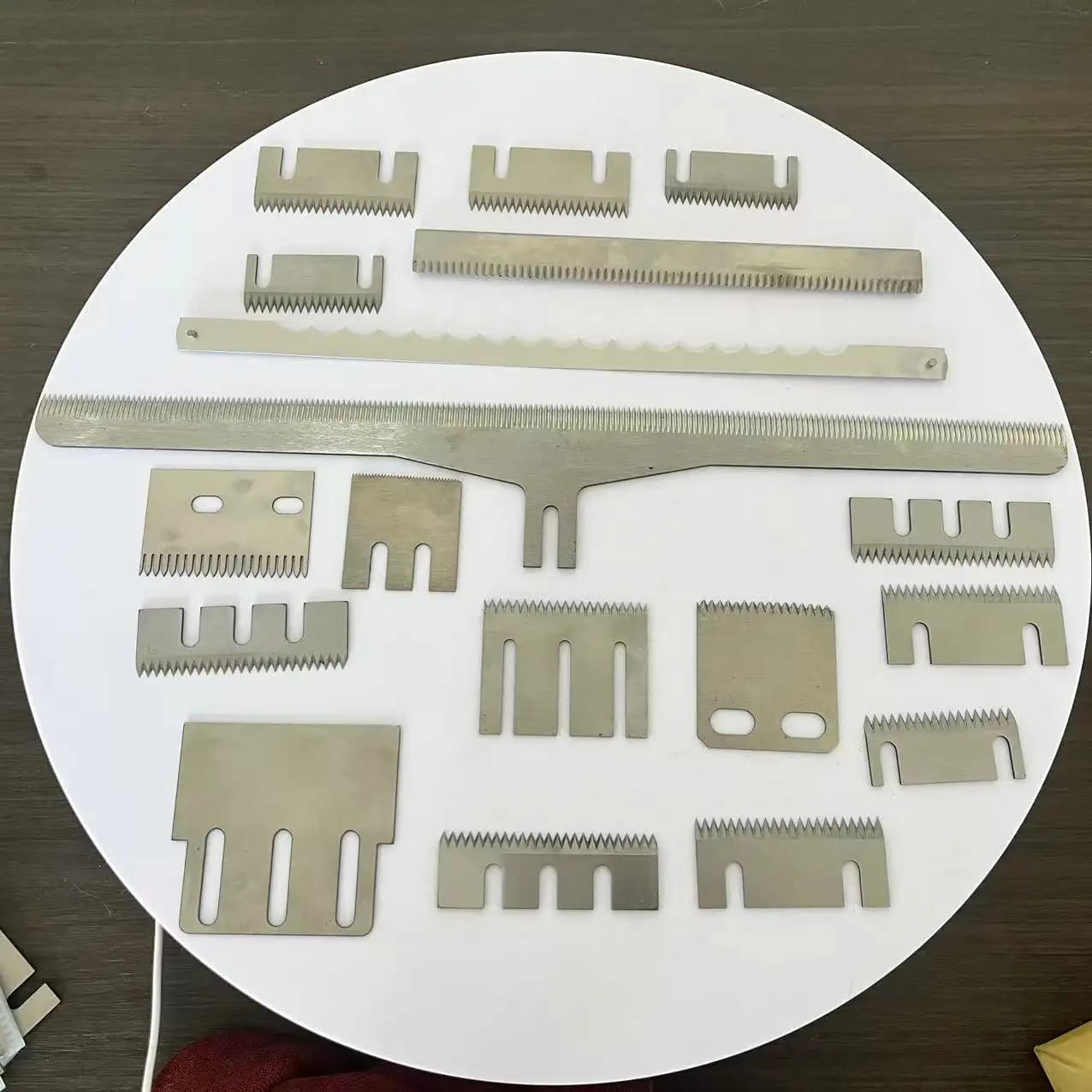

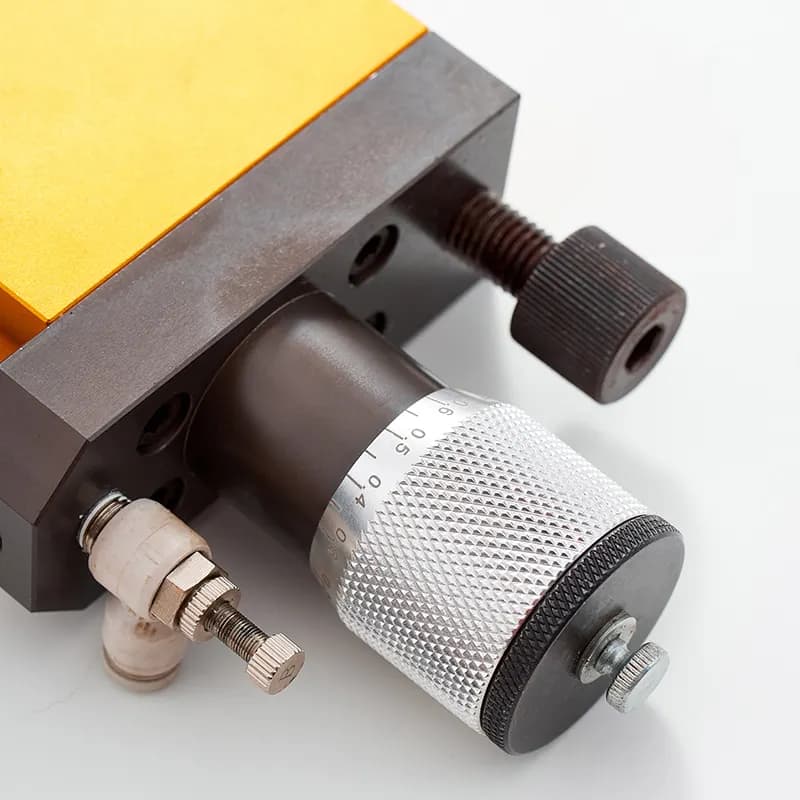

The pneumatic knife holder accessories are designed to enhance the efficiency and precision of industrial cutting applications. These advanced tools are equipped with a robust set of features that cater to the needs of various industries. The main functions of the pneumatic knife holder include secure blade mounting, precise depth adjustment, and pneumatic actuation for effortless and repeatable cutting. Technological features such as an air-powered mechanism, a locking system for safety, and compatibility with a range of blade types make it a versatile choice for different materials. Its applications span across packaging, food processing, textile manufacturing, and more, where reliability and speed are crucial.