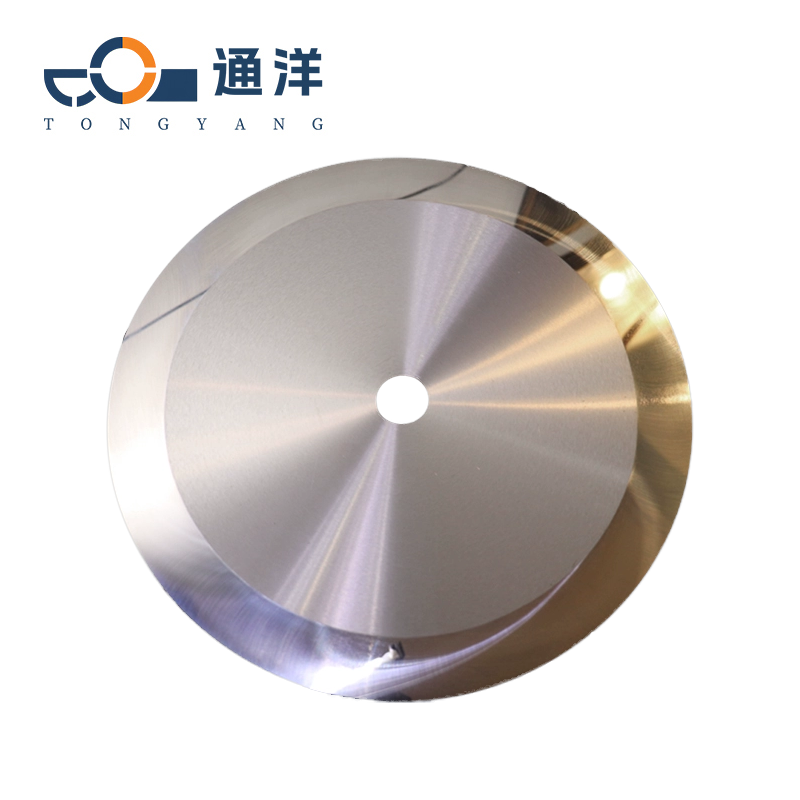

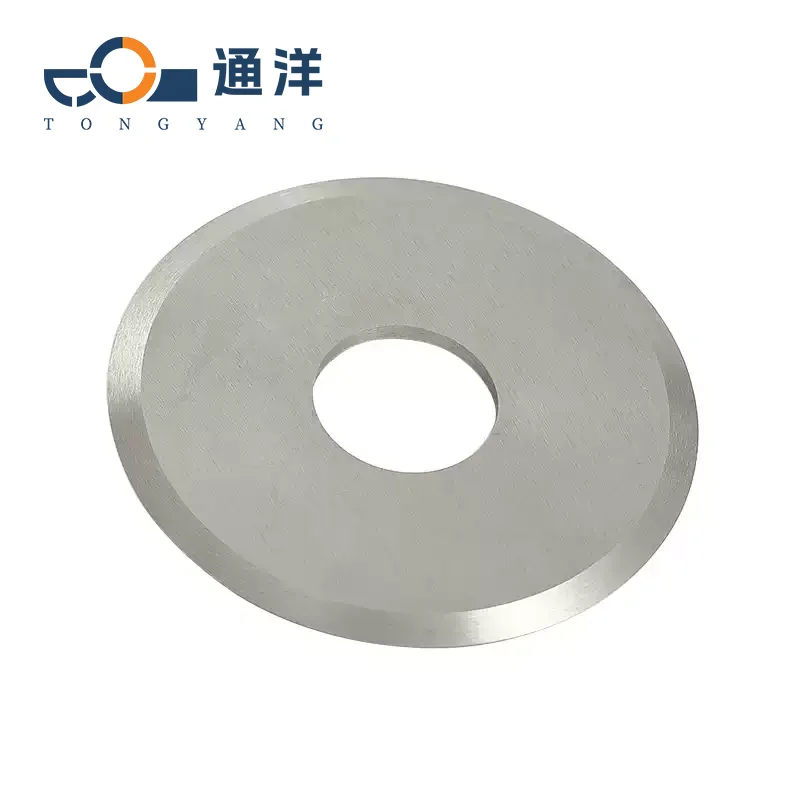

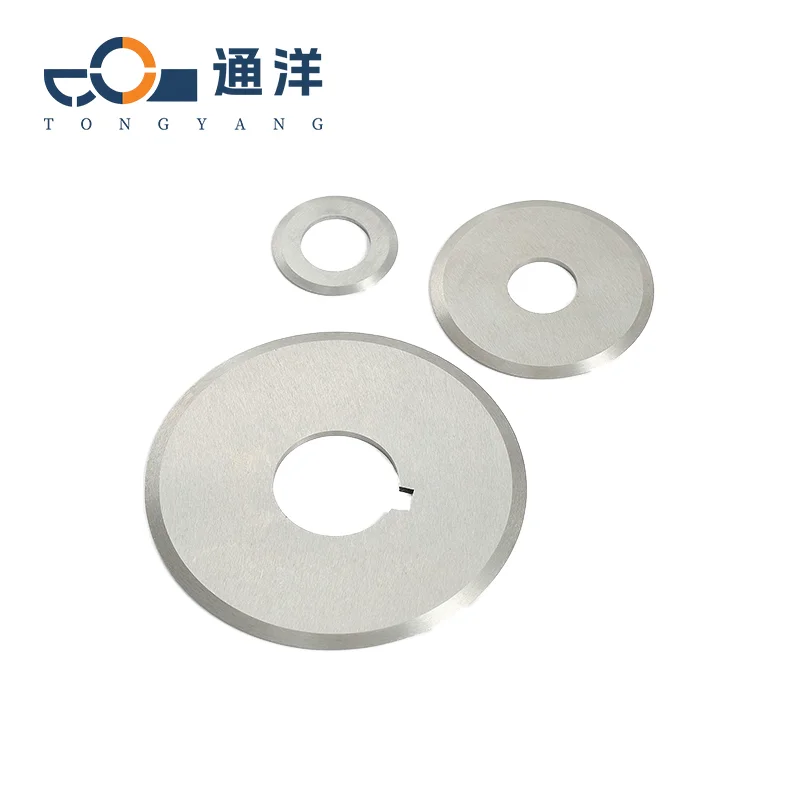

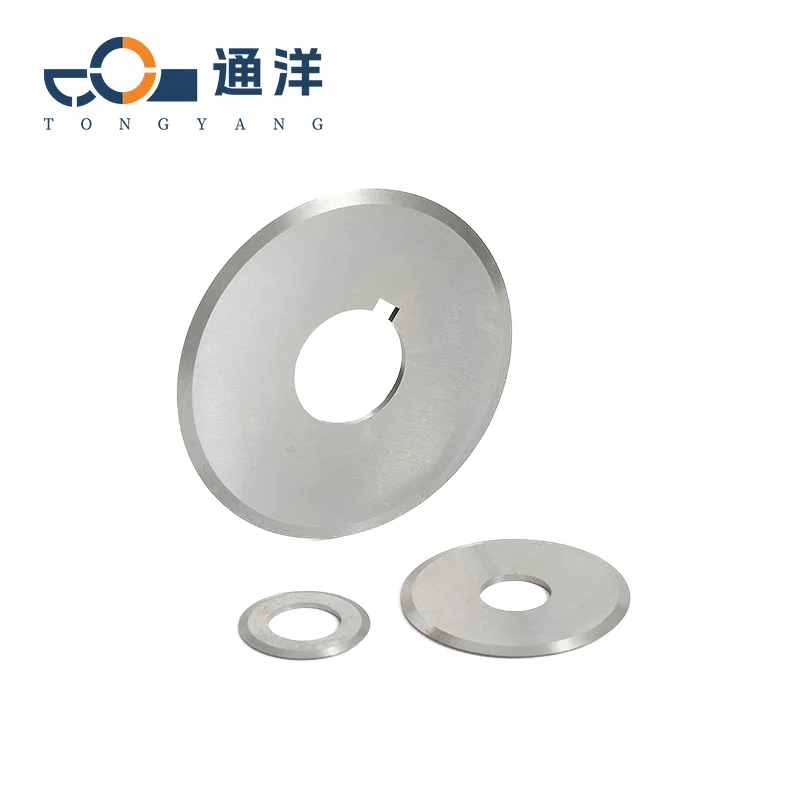

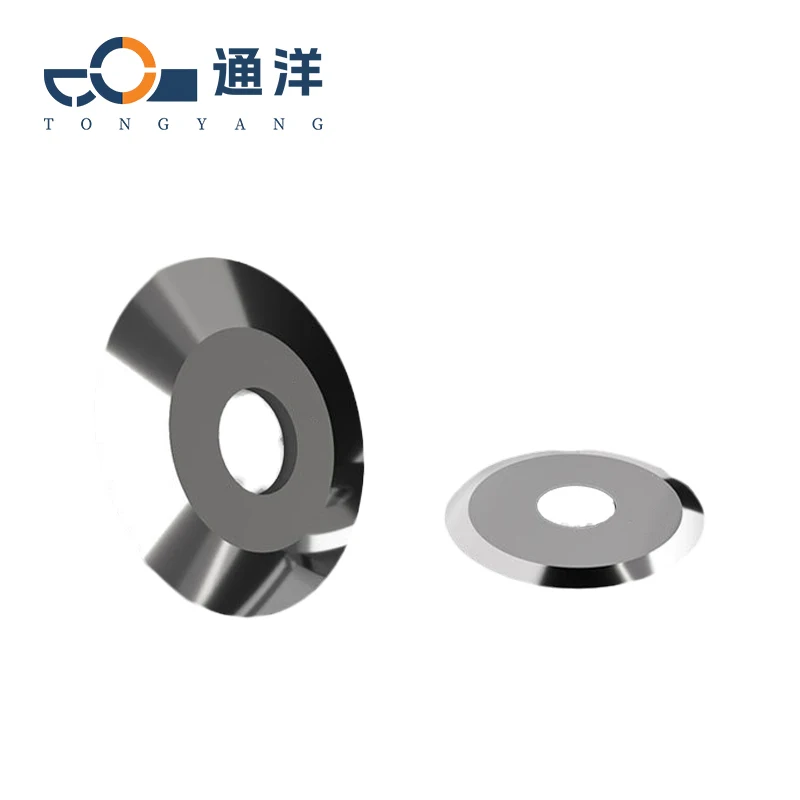

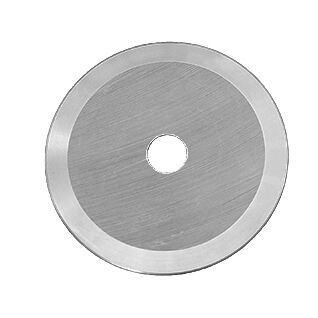

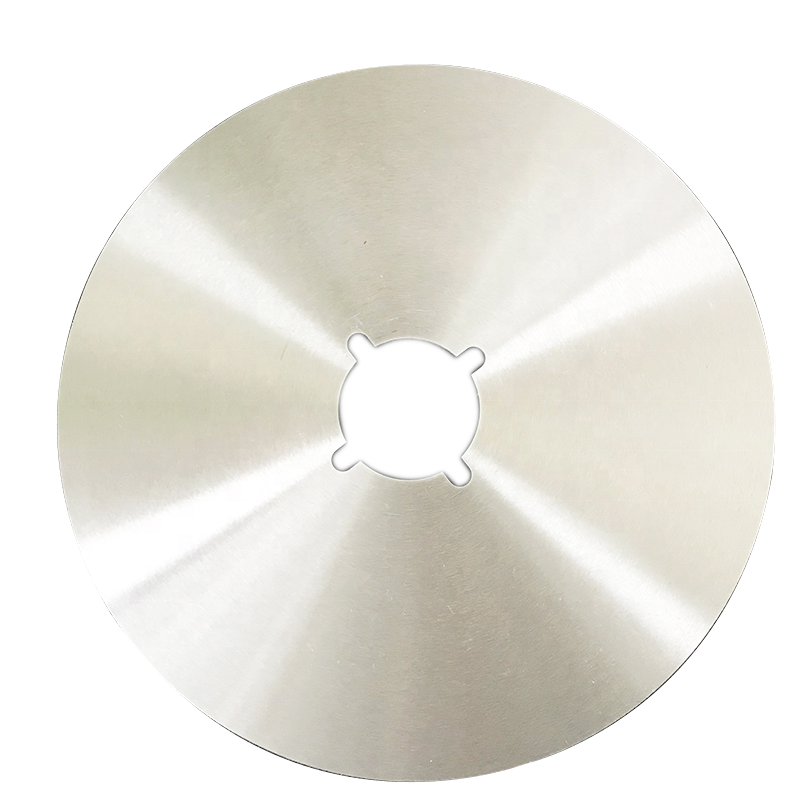

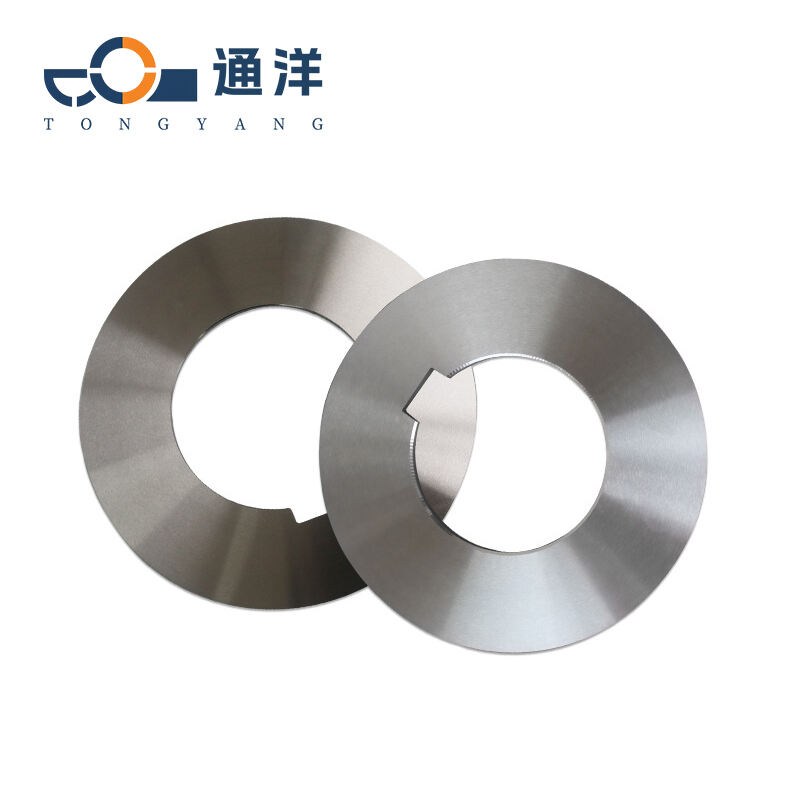

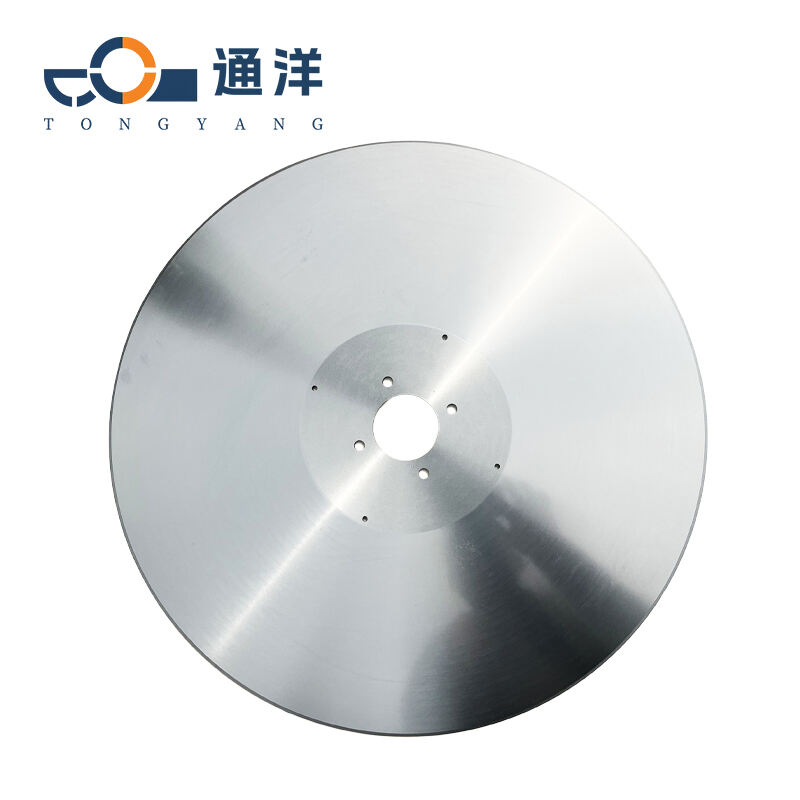

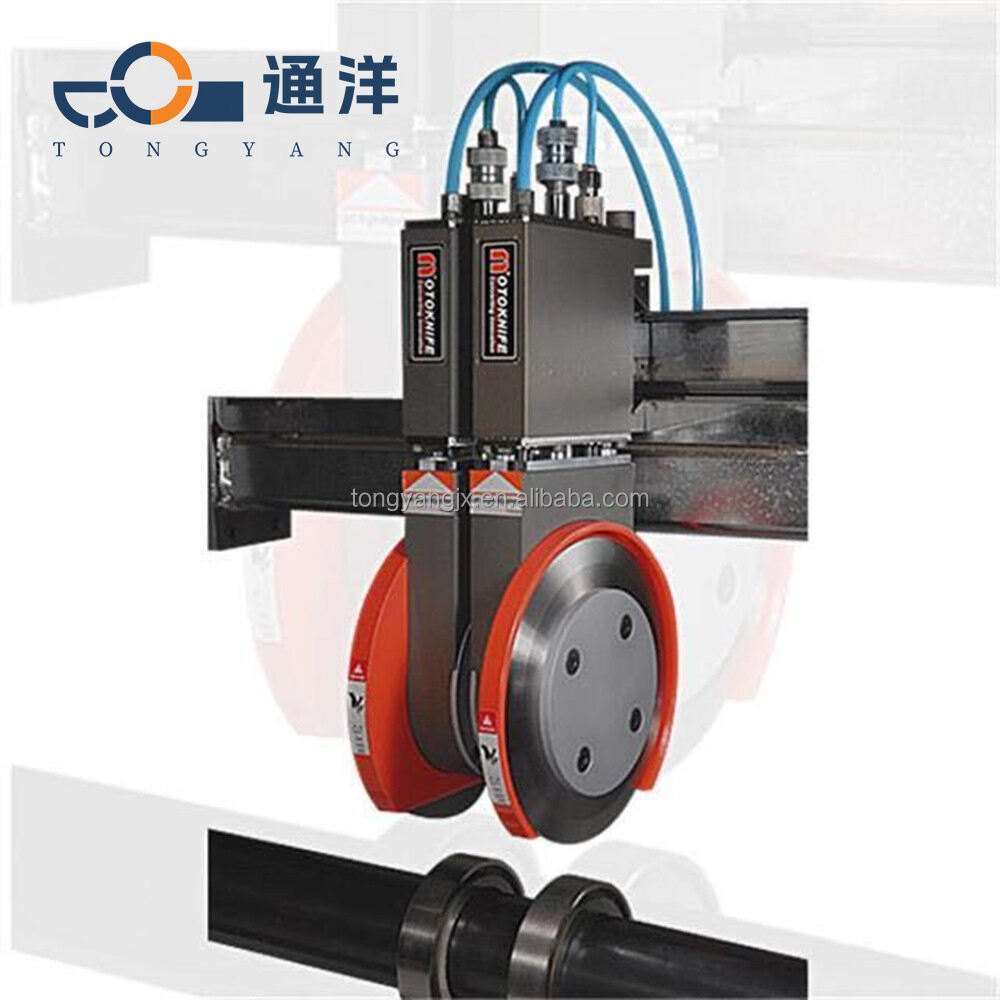

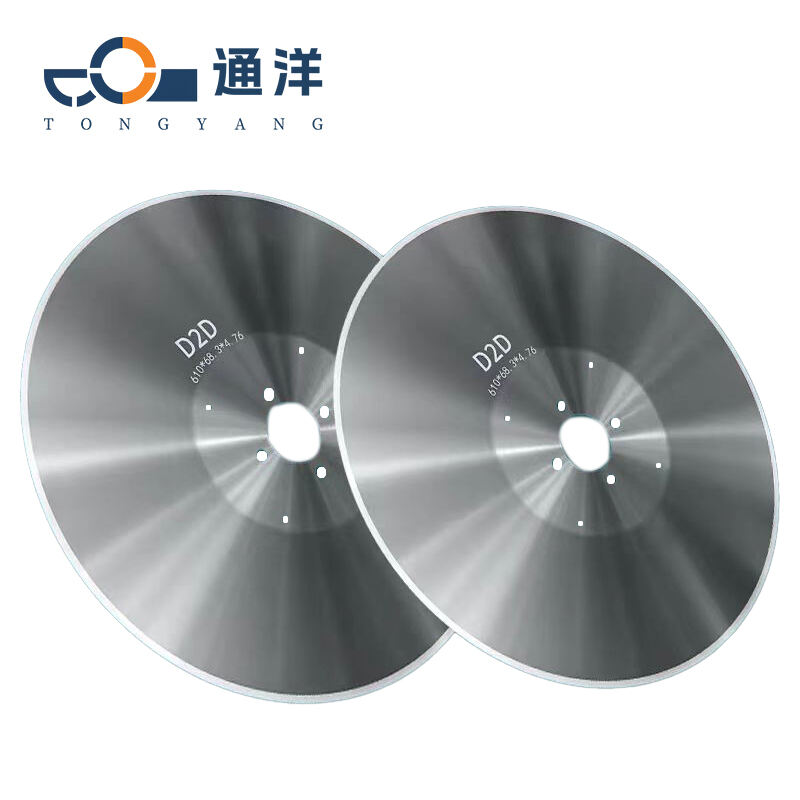

Round knife for food cutting

- Overview

- Related Products

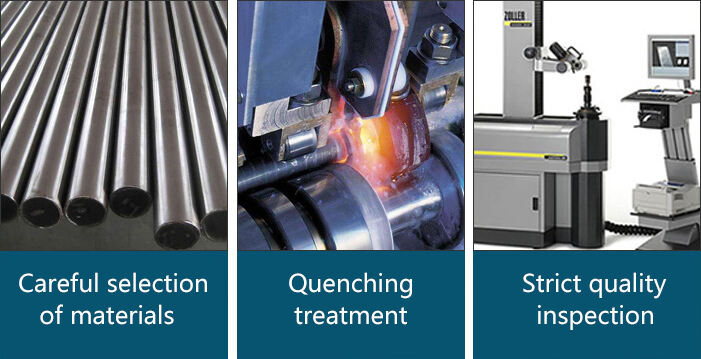

Material

Stainless Steel Material

304 Stainless Steel: A commonly seen food-grade material with good corrosion resistance. It can resist the

erosion of acids and alkalis in most foods, is not prone to rusting, has good toughness and strength, and can

withstand a certain degree of bending and impact without being easily broken. Its surface is smooth and easy

to clean, and it will not adsorb food residues and bacteria, meeting food safety standards. It is widely used in

round knives for food cutting.

316 Stainless Steel: It has stronger corrosion resistance than 304 stainless steel, especially showing

outstanding resistance to some chlorine-containing media. This makes it perform more excellently when

handling some foods that may contain salt or other corrosive components. For example, in the fields of

processing pickled foods, seafood etc., round knives made of 316 stainless steel can better maintain the

performance and appearance of the knives and have a longer service life. However, the cost of 316 stainless

steel is relatively high, so the price of round knives made of this material is slightly more expensive than those

made of 304 stainless steel.

Ceramic Material:Round knives made of zirconia ceramic are made of zirconia.They have extremely high

hardness with the hardness only second to that of diamond. The blades are sharp and wear-resistant, remaining

sharp for a long time and reducing the frequency of sharpening. These ceramic round knives do not react with

food, and they will not affect the taste and color of the food. They are very suitable for cutting various foods,

especially those with high requirements for smell and color, such as fruits and vegetables In addition, the ceramic

material has good antibacterial properties and is not prone to the growth of bacteria. However the ceramic round

knives are brittle and easy to break, so special care should be taken during use and storage to prevent dropping

and avoid collision with hard objects.

There are also some round knives that use special coating materials, such as titanium nitride coating. This

kind ofcoating can improve the hardness, wear resistance and corrosion resistance of the knife. At the same

time, it can also make the surface of the knife smoother, reduce the adhesion between food and the knife

surface and make the cutting process smoother.

Stainless steel material: Both 304 and 316 stainless steels are food-grade. Relying on the passive film

formed on itssurface, 304 stainless steel can effectively resist the erosion of acids and alkalis in common

foods, and there is no risk of metal ion precipitation. It is widely applicable in scenarios such as cutting

vegetables in daily kitchens and processing dough in bakeries

Advantages of cutting meat with a round knife

Flexible Adaptation: The circular structure enables the round knife to rotate flexibly and adjust its angle at

will during cutting. It can perfectly conform to the curves of the fish body and irregular parts such as the fish

head and tail Whether it is slicing the fish or handling complex parts, it can be easily dealt with, reducing

obstacles and achieving excellent cutting efficiency and precision.

Maintaining Integrity: Compared with sharp straight knives, the blade of the round knife is relatively blunt

When dealing with soft fish meat such as bass and mandarin fish, it is not easy to pierce or chop the fish

meat due to excessive force. It can completely preserve the shape of the fish meat, and the sliced fish fillets

and fish pieces are in regular shapes, which is beneficial for cooking and arranging on the plate.

Reducing Splashing: The round knife cuts in a rolling manner instead of chopping like a straight knife, which

can greatly reduce the splashing of fish meat and juice, keep the operation area clean and tidy, and avoid the

loss of nutrients with the juice

Precise Thickness Control: According to the cooking needs, the round knife can easily cut the fish meat into

uniform thin slices for sashimi and steamed fish slices, or cut it into fish pieces of appropriate thickness for

braising and stewing, effectively improving the cooking effect and taste of the dishes

Maintenance Process

1.Timely Cleaning: Immediately after cutting the fish, rinse the round knife with warm water to remove stains such

as fish meat residues, bloodstains, and mucus. Do not use hot water to prevent the knife body from deforming.

2.Gentle Cleaning: If the stains are difficult to remove, use a mild dishwashing liquid or a specialized kitchenware

cleaner. Gently wipe the surface of the knife with a soft cloth or sponge. Do not use a steel wool scrubber to avoid

scratching the knife.

3.Thorough Drying: After washing, use a dry towel or kitchen paper towel to thoroughly dry all parts of the round

knife, including the blade edge, the back of the blade, and the handle, to prevent the knife from rusting due to

water residue

4.Applying Cooking Oil: Apply a thin layer of olive oil or regular cooking oil on the surface of the knife to form a

protective film, preventing the knife from rusting due to contact with air and water. Wipe off the excess oil after

application to avoid the accumulation of dirt

5.Proper Storage: Place the round knife in a dry and ventilated place. Do not store it together with other knives

or hard objects to prevent the blade edge from being collided or scratched. You can use a knife rack or a knife

sheath for storage to protect the blade edge