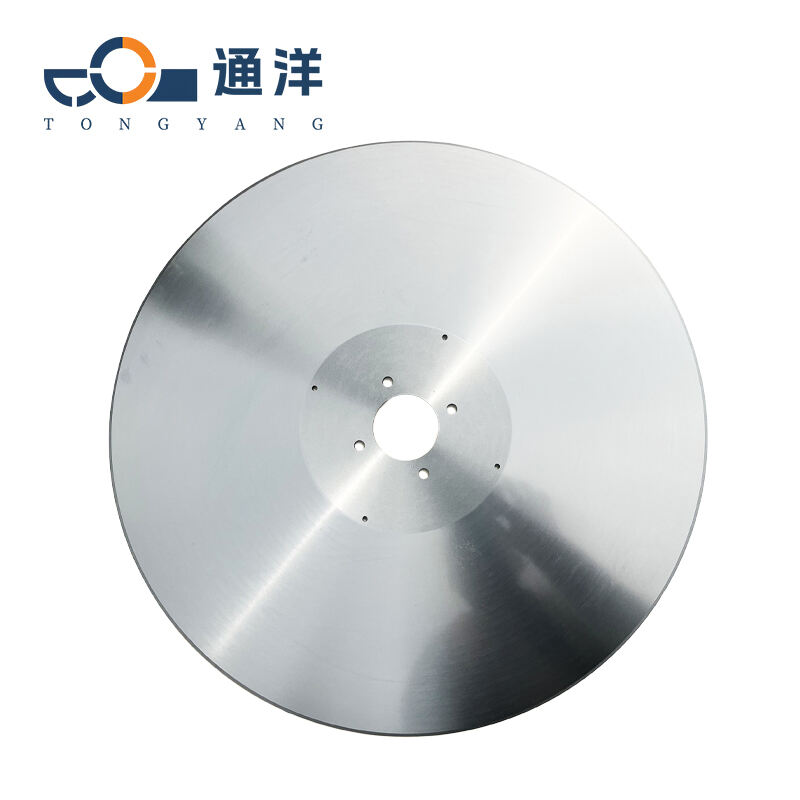

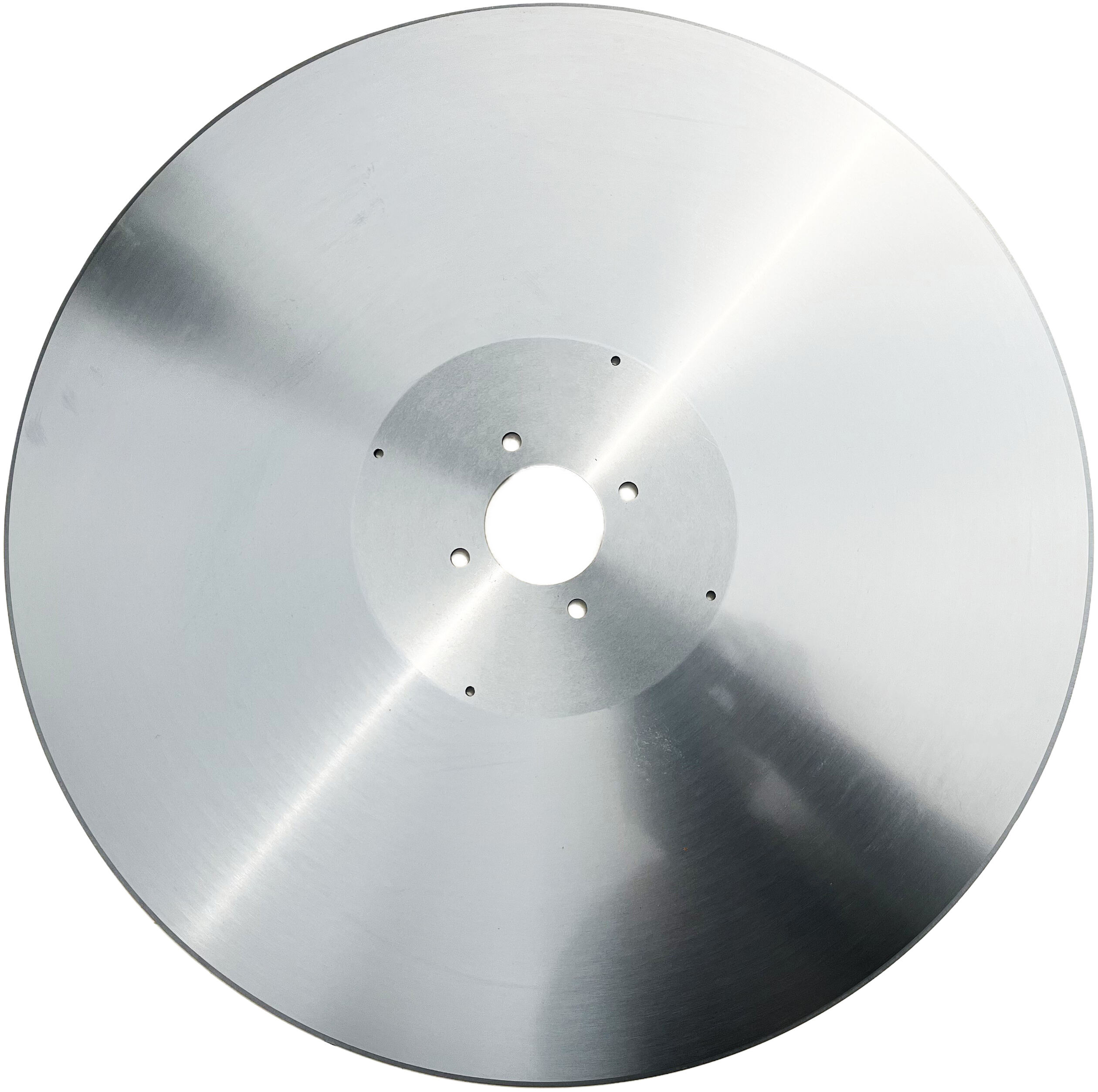

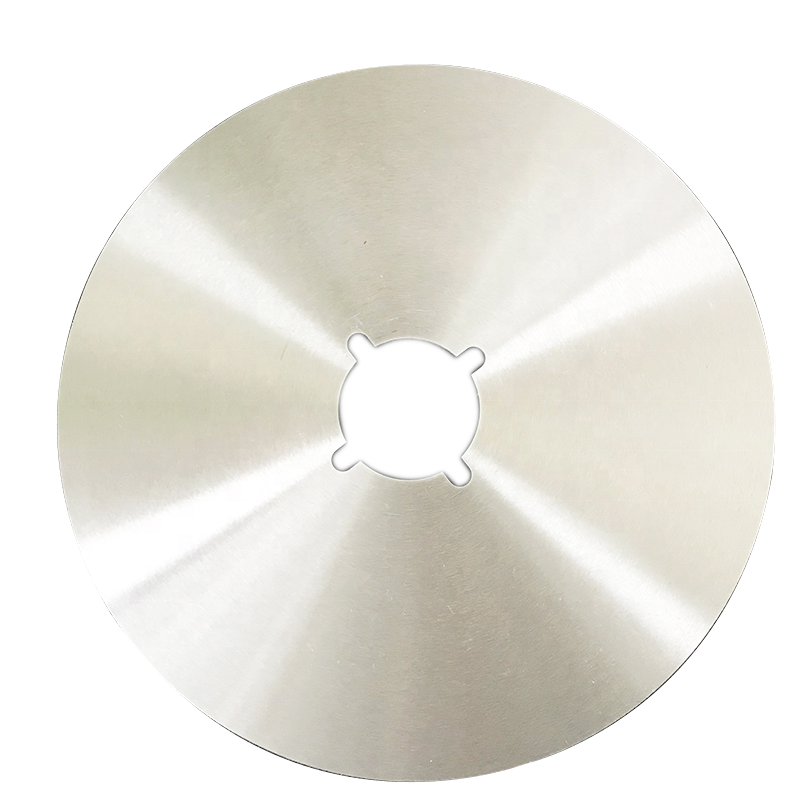

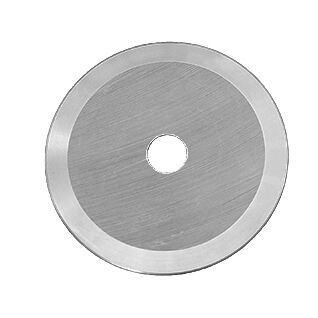

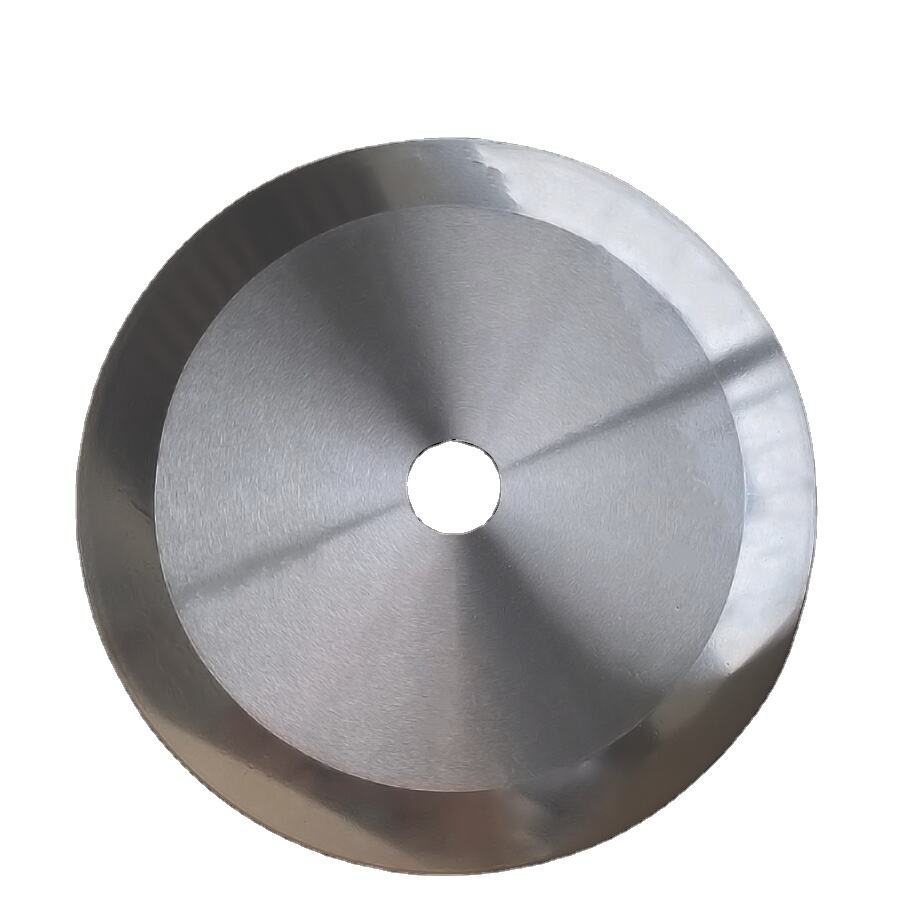

Circular paper cutting knife

- Overview

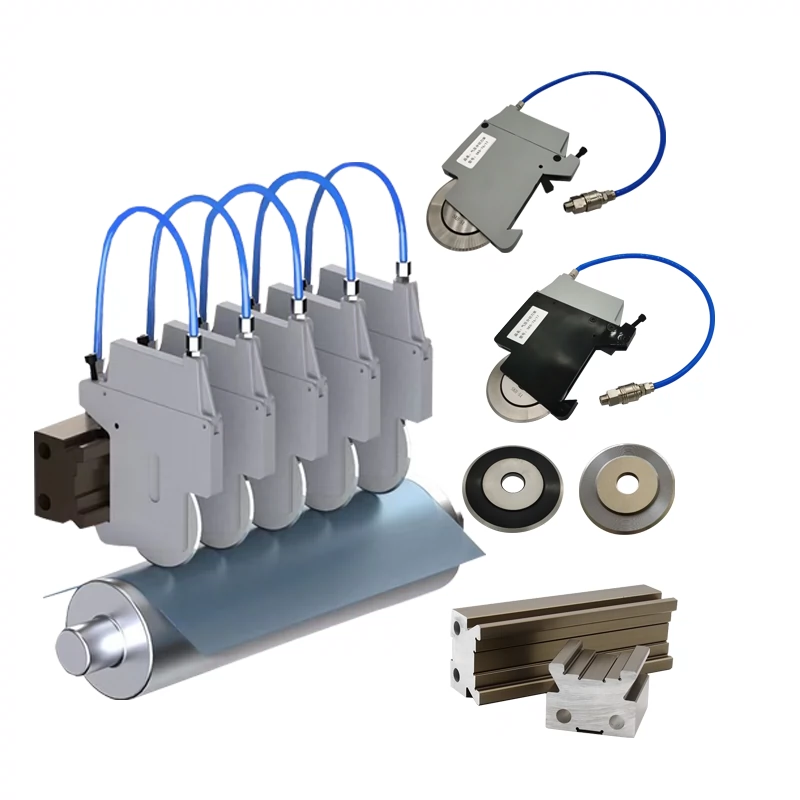

- Related Products

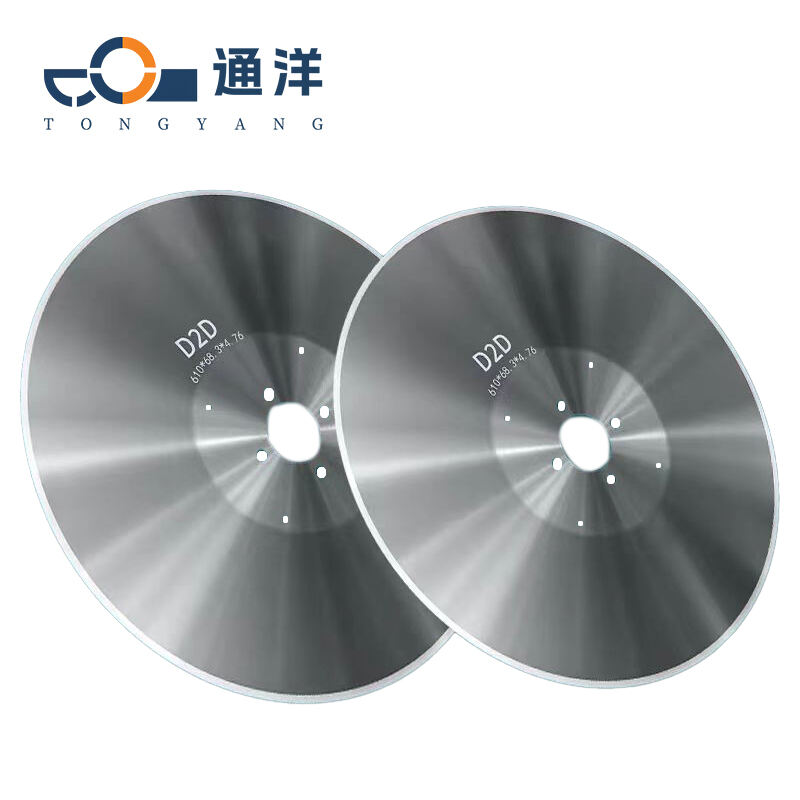

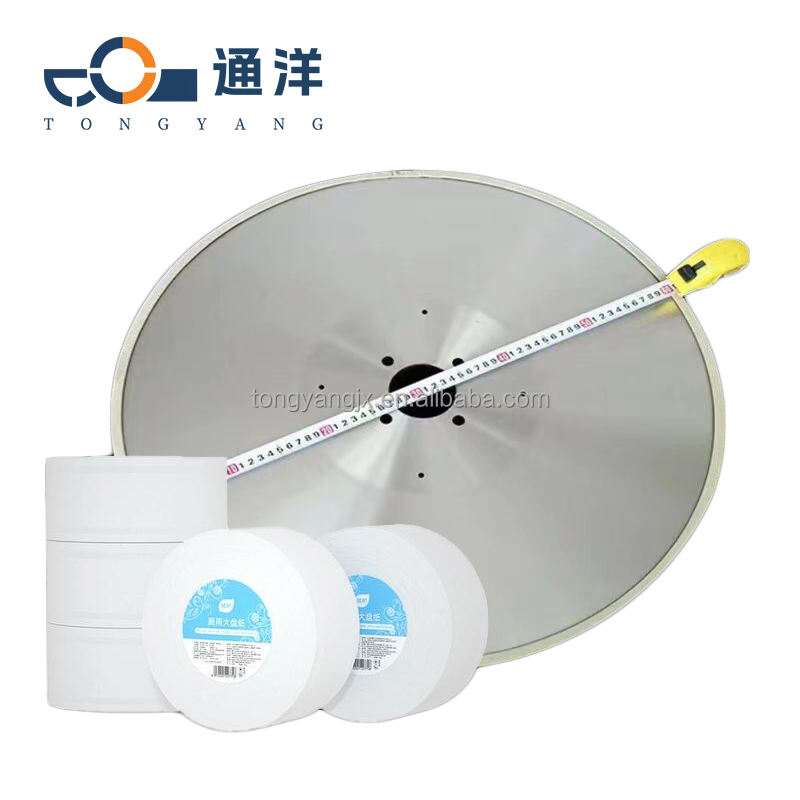

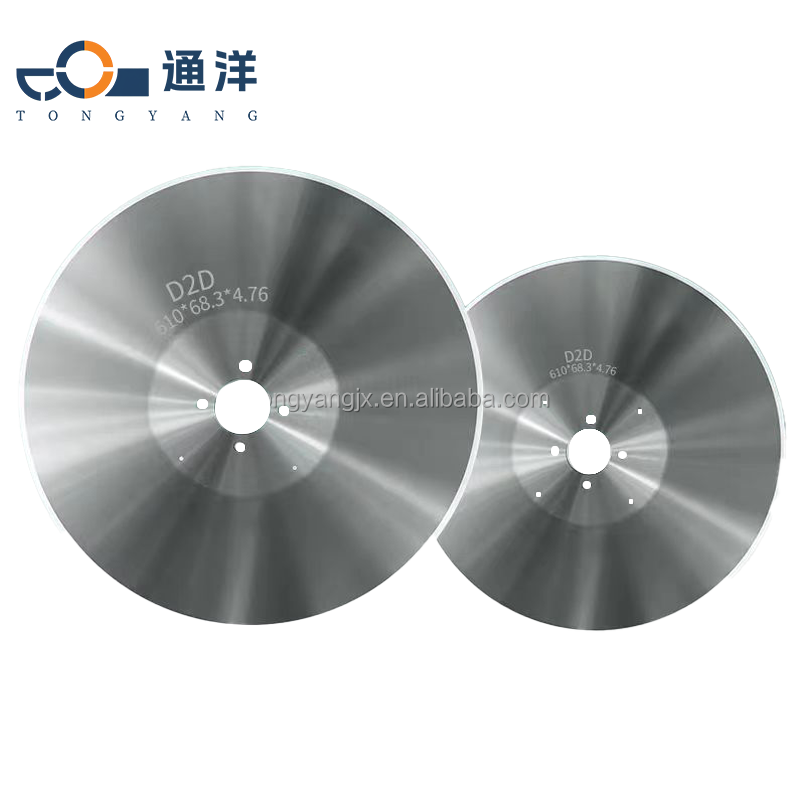

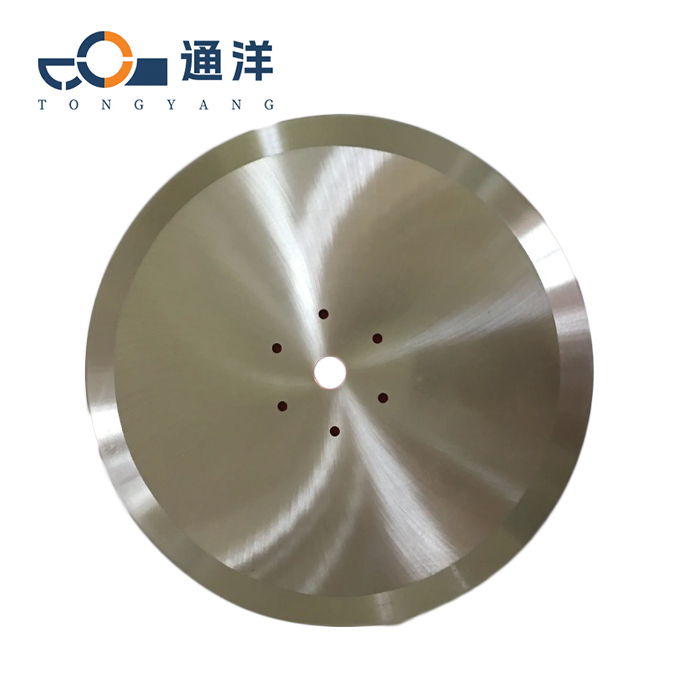

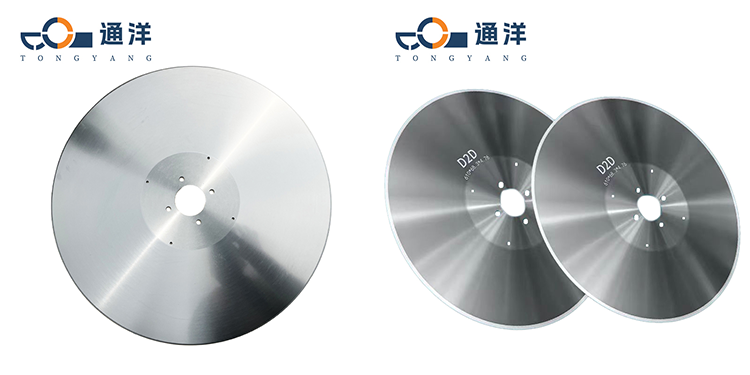

610 slitting blade for textile and tissue paper

The blade adopt d2 material, longer.service life, the tolerance can reach to OD:+0.1,ID:+0.03-0.00,Thickness:

+0.03, can be used for paper, textile, wood and etc.

standard size for 610mm blade

Diameter 610 x Bore 68.26 x Thickness 4.76

Diameter 610 x Bore 68.26 x Thickness 3.80

Diameter 610 x Bore 82.55 x Thickness 4.76

Diameter 610 x Bore 68.26 x Thickness 3.80

Diameter 610 x Bore 100 x Thickness 4.76

Diameter 610 x Bore 100 x Thickness 3.80

Diameter 810 x Bore 60 x Thickness 6.0

| Place of origin | Anhui.china |

| Warranty | 6 Months |

| Material | D2,M2,52100 or customized |

| Hardness | 58-60 HRC |

| OEM Service | Support |

Metal material

| Material | Material grade | Features |

| Tool steel | SK5、SK7 |

It has a low cost and high hardness, and is suitable for ordinary paper and thin cardboard (such as office paper and advertising paper). It needs to be sharpened regularly. |

| High-speed steel (HSS) | M2、M35 |

It is wear-resistant and resistant to high temperatures (suitable for high-speed cutting), and is suitable for materials of medium hardness (coated paper, cardboard). Its service life is 2 to 3 times that of tool steel. |

| Cemented carbide (tungsten steel) | YG8、YG15 |

It has extremely high hardness and wear resistance, and is suitable for hard materials (thick cardboard, corrugated paper, fiberboard). The cutting edge has a long service life, but it is highly brittle. |

| Stainless steel | 440C |

It is corrosion-resistant (suitable for paper with coatings or in a humid environment). Its hardness is lower than that of tool steel, and it is used for ordinary paper or special coated paper. |

| material | Features | apply to |

| Ceramics (Zirconia) | The hardness is HRA 90+ with long-lasting sharpness. There is no pollution of metal ions, but it has high brittleness. | High-precision slitting of label paper and films. |

| CVD coating | Tool steel/high-speed steel substrate + TiN/TiC coating, the hardness is increased to HRC 65+, and it is wear-resistant and corrosion-resistant. | High-speed slitting machine, which can extend the service life of the cutting tools by more than 30%. |

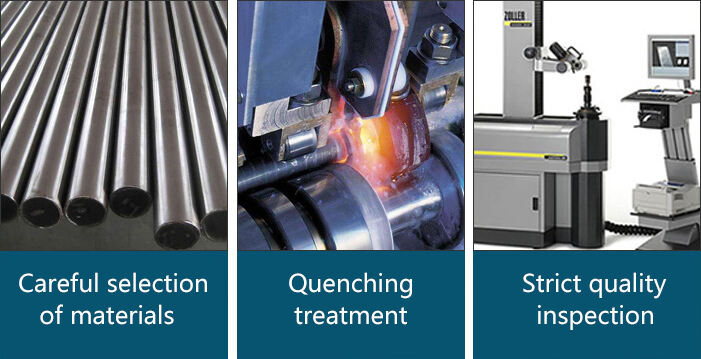

Our Advantages

Size classification

| parameter | specification | apply to |

| Diameter (φ) | φ100mm - φ600mm (Customized according to requirements) | φ150mm, φ200mm, φ300mm (for slitting machines) |

| Thickness (T) | 1mm - 8mm (The thickness affects the cutting precision) | 2mm (thin paper), 5mm (thick cardboard) |

| Aperture (d) | φ20mm, φ25mm, φ32mm, φ50mm (to match the shaft diameter of the equipment) | φ25mm (for standard slitting machines) |

| Edge angle | 15°-30° (An acute angle is suitable for thin paper, and an obtuse angle is suitable for thick materials) | 20° (Universal), 25° (Thick cardboard) |

Application area

Paper making industry

During the papermaking process, the paper produced is usually in large rolls. It is necessary to

use a circular knife to slit it into small rolls or flat sheets of paper in different specifications to

meet the needs of various customers. The high precision and sharpness of the circular knife

can ensure that the paper cut is neat and smooth, without burrs, thus improving the quality and

appearance of the paper.

Printing industry

The circular knife can quickly and accurately complete the cutting task, improving production

efficiency. At the same time, it ensures the accuracy of the cutting dimensions, meeting the

high-quality requirements of printed products.

Packaging industry

For the processing of packaging materials and the production of cartons of various specifications

in the field of plastic film packaging, the circular knife can be used to slit the coiled plastic

film into packaging materials of specific widths for the packaging of products.

Textile industry

Whether it is cutting large rolls of fabric into pieces of cloth of different lengths or precisely

cutting the cut pieces in the garment production process, the circular knife can, with its

efficient and accurate cutting performance, improve the efficiency and quality of fabric

cutting and reduce fabric waste.

Leather industry

The circular knife is used to cut the whole piece of leather into leather parts of various shapes

and sizes, which are used to make leather products such as leather shoes, leather bags, leather

jackets and so on. The circular knife can achieve smooth and neat cutting on the leather,

avoiding the tearing or roughness of the leather edges, which helps to improve the quality and

appearance of leather products.

Rubber industry

In the production of rubber products, such as the processing of rubber sheets, rubber hoses

and other products, the circular knife can cut rubber materials into different specifications and

shapes according to production requirements, meeting the production process requirements

of rubber products.

Basis for Material and Model Selection

| Core parameters for equipment selection and processing technology design | Specific selection |

| Material hardness |

Ordinary paper (60-100g/m²): Tool steel (SK5) or stainless steel (440C) Thick cardboard (above 200g/m²): High-speed steel (M2) or cemented carbide (YG8) Special materials (coated paper, film): Ceramic knives or knives with TiN coating. |

| Equipment speed |

Low-speed equipment (< 100m/min): Tool steel High-speed equipment (> 300m/min): High-speed steel or coated knives |

| Cutting precision |

High precision (±0.1mm): Cemented carbide or ceramic knives (the sharpness of the cutting edge ≤ 10μm) General precision (±0.5mm): Tool steel or stainless steel. |

| Equipment interface |

Installation methods: Flange type (commonly used), sleeve type, expansion sleeve type Aperture matching: Select according to the size of the main shaft of the slitting machine (such as φ25mm, φ32mm) |

Maintenance and Service Life

Sharpening cycle: Tool steel (50-100 hours) < High-speed steel (200-300 hours) < Cemented carbide (500

-800 hours)

Influencing factors of service life: Material hardness (for example, sand-containing paper accelerates wear)

sharpness of the cutting edge, and equipment stability (vibration leads to chipping of the cutting edge).

Storage suggestions: Protect with antirust oil (for metal knives), and avoid collisions (for ceramic knives).

Summary of the Selection of Circular Paper-cutting Knives

The key to model selection: clearly define the cutting material (gram weight, number of layers)equipment

parameters (speed, shaft diameter), and precision requirements.

General scenarios: Tool steel (SK5) + Conventional models (φ150-200mm)

High-end requirements: Cemented carbide/ceramics + coating technology + customized specifications

(serrated/stepped cutting edges)