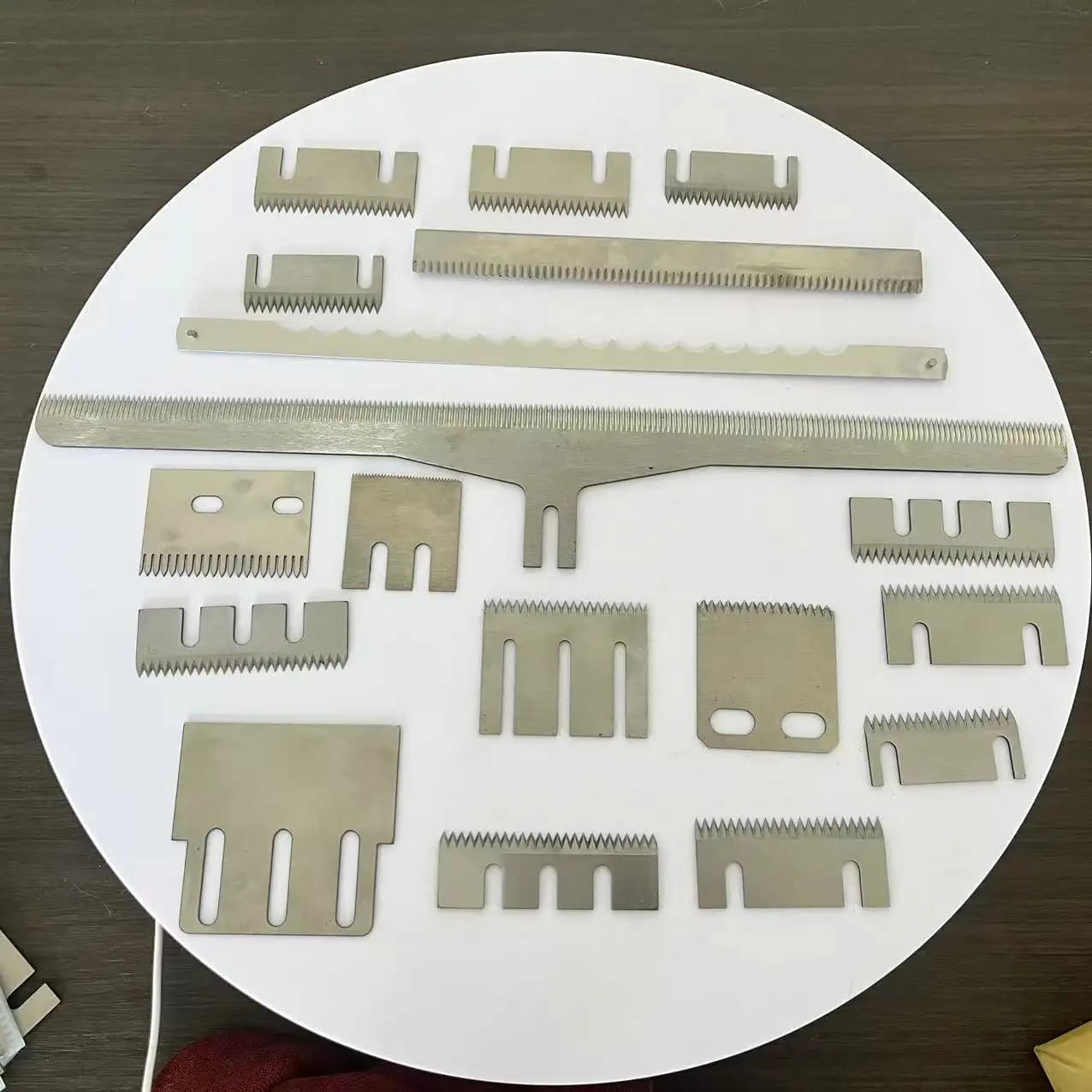

plastic wood pulverizer machine accessories

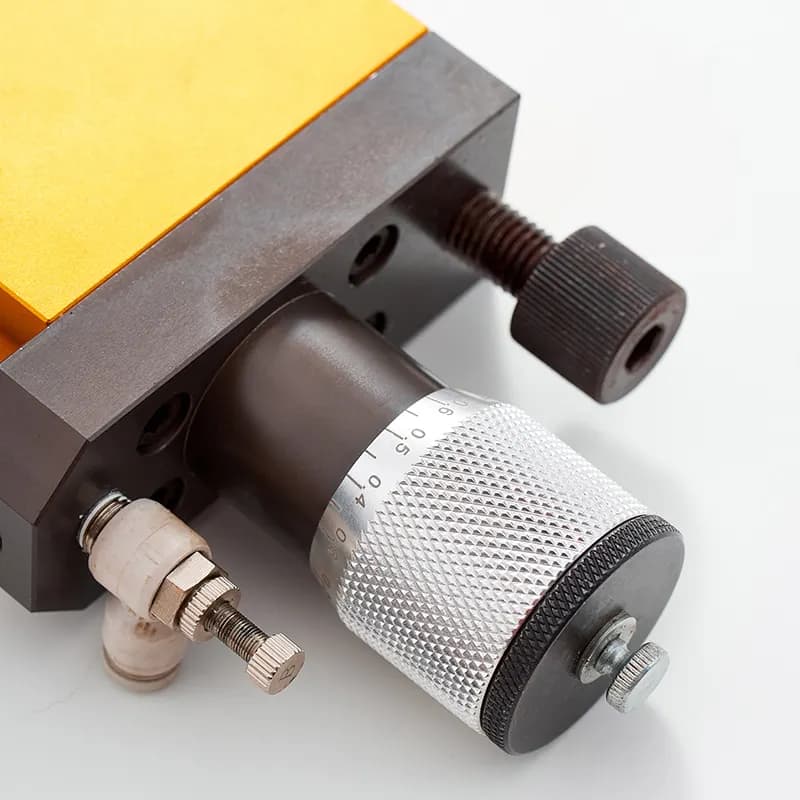

The plastic wood pulverizer machine accessories encompass a variety of components designed to enhance the performance and longevity of the pulverizing process. These accessories include cutting blades, screens, filters, and shafts, all meticulously crafted to work in unison with the main machine. The primary functions of these accessories are to grind and粉碎 wood and plastic materials into fine particles, making them suitable for recycling and repurposing. Technological features such as precision engineering and heat-treated materials ensure durability and efficiency. Applications span across industries such as construction, manufacturing, and waste management, where the conversion of wood and plastic waste into valuable resources is crucial.