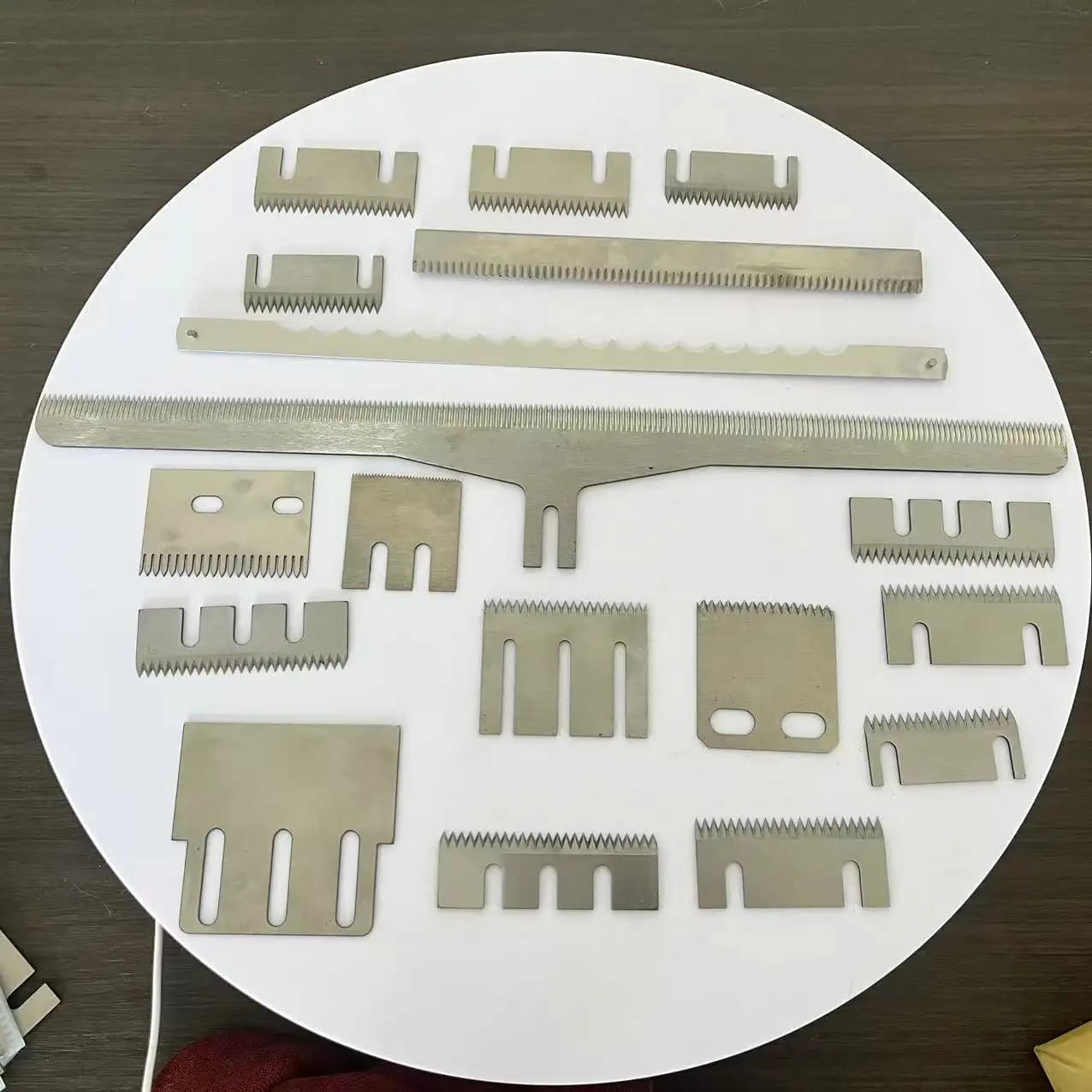

core cutting round blade 3 inch

The core cutting round blade 3 inch is a precision tool designed for clean and accurate cuts through a variety of materials. With a diameter of 3 inches, this blade is versatile enough for both large-scale industrial applications and detailed crafting projects. The blade's main functions include cutting through metals, plastics, and woods with ease, offering a high-speed and high-efficiency solution for workshops and manufacturing units. Technological features such as a tungsten carbide tipped edge ensure durability and longevity, providing a sharp cutting performance that resists wear and tear. The applications of the core cutting round blade are diverse, ranging from HVAC installations to electrical work and general construction, making it an indispensable tool for professionals across multiple trades.