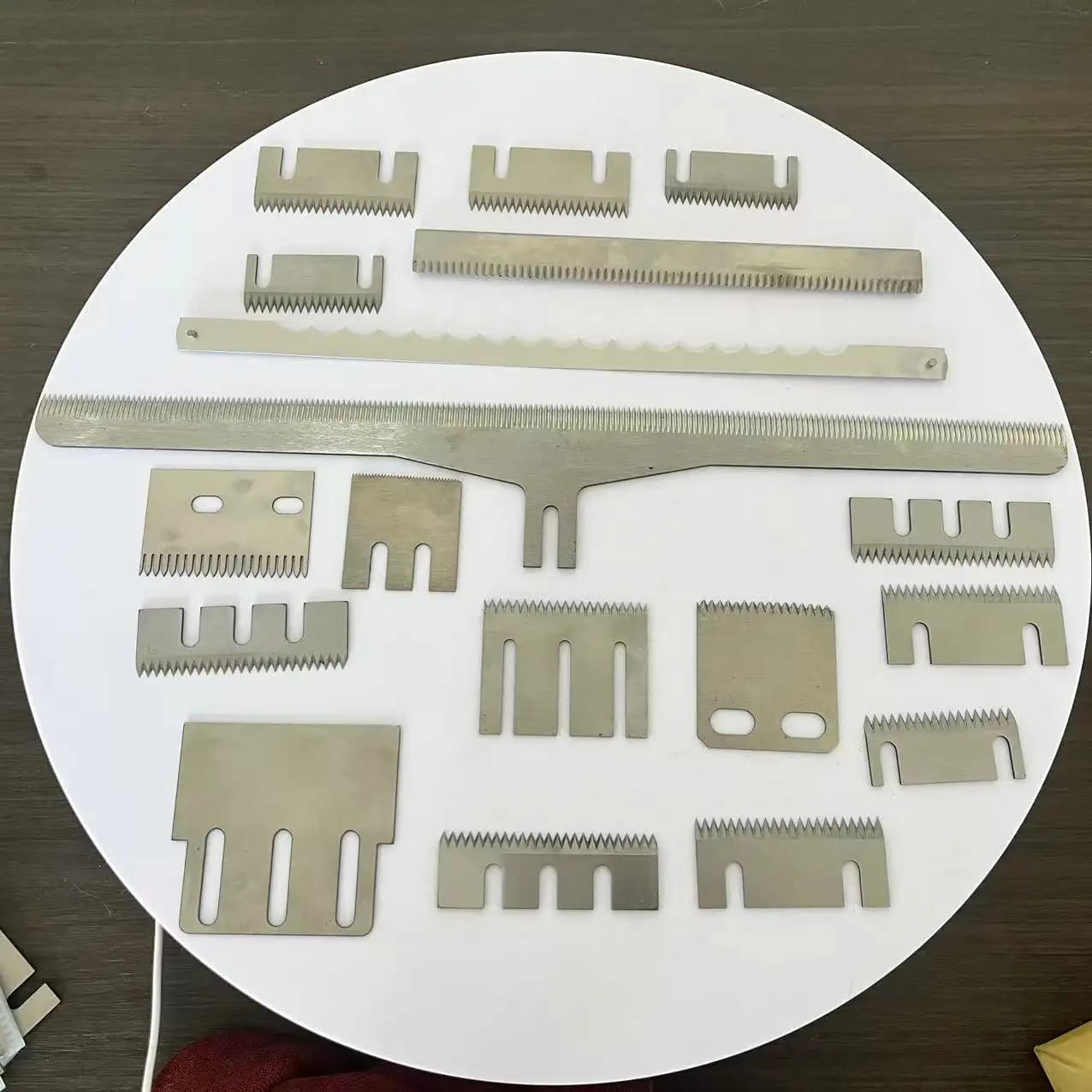

blades for chipper

The blades for a chipper are the heart of the wood-processing machine, designed to effectively reduce branches, wood, and other materials into manageable chips. Engineered for durability and performance, these blades undergo meticulous crafting to ensure they can withstand the rigors of continuous operation. Their main functions include cutting, shearing, and shredding, enabling the chipper to process materials efficiently. Technological features of these blades include a high-carbon steel composition, which offers exceptional hardness and wear resistance. Moreover, their heat-treatment process ensures a balance between hardness and toughness, minimizing the risk of breakage. These blades find applications in various sectors, including landscaping, forestry, and biomass energy production, making them an indispensable tool for managing organic waste and reducing environmental impact.