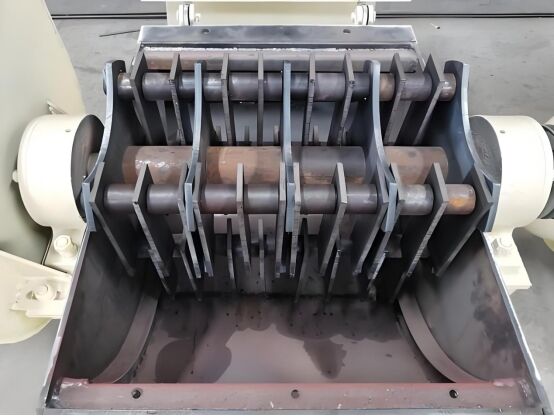

Many manufacturers are frequently changing industrial blades, not because they are inappropriate, but because industrial blades are too easy to wear in the process of use. Part of the reason is because of the quality of industrial blades, and one is caused by poor maintenance in normal times, good industrial blades must have good maintenance in order to play his maximum effect. Especially for some metal, some wood on the broken, the requirements for industrial blades is very high, if it is frequent use, I believe that industrial blades will soon wear, the following I will introduce to you how to maintain the blade method.

First: can not be used frequently. Any machine will have his life, we can not be infinite to extend his life, only in the life to improve. For me, the most important thing is to reduce the use, many businesses do not pay attention to the protection of industrial blades, so they are used all day long, even if it is a good quality blade, it will not withstand such a large workload.

Second: always pay attention to the lubrication of industrial blades. The machine also needs to be lubricated, when the industrial blade is working, no matter what type, it will produce very large heat, at this time, if you do not pay attention to the lubrication of the industrial blade, it is easy to make the blade and the machine friction, spend a little time to add lubricating oil to the machine, on the one hand, in order to protect the blade, on the other hand, it can also improve the efficiency of the work.

Third: multiple times of cleaning. Industrial blades also need to be cleaned, a lot of times, especially when the paper or wood is broken, you must pay attention to the cleaning of the blade, so that the industrial blade is always working without friction, you can further achieve the purpose of maintenance.

Hot News

Hot News

Copyright © 2025 Ma 'anshan Tongyang Machinery Equipment Co., Ltd. All rights reserved. Privacy policy