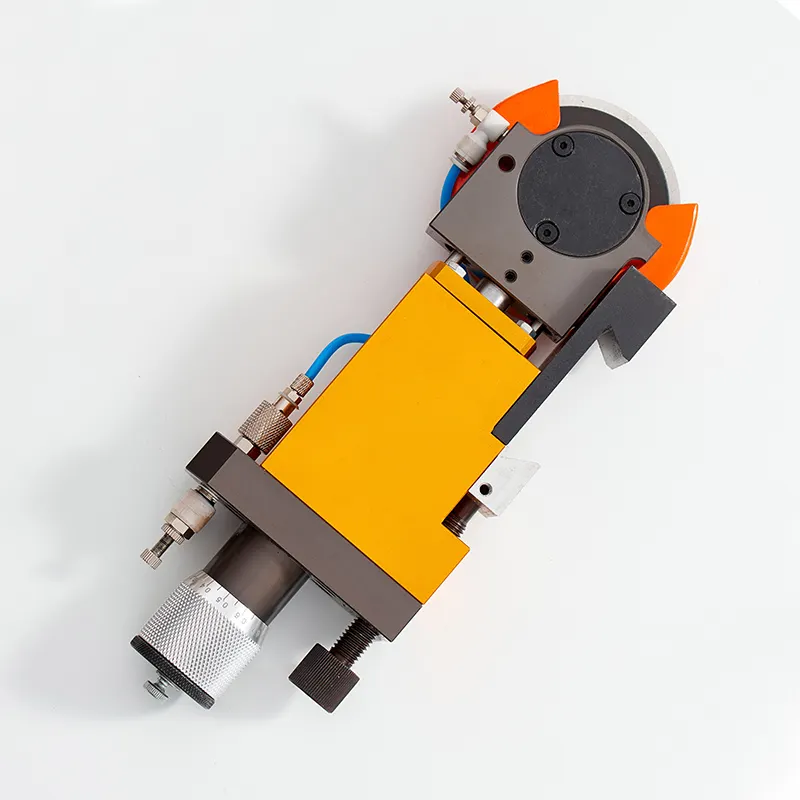

Pneumatic blade holders provide precise cutting solutions for various industries. You can rely on these tools for tasks like slitting, perforating, and trimming. Their design ensures consistent performance, even in demanding environments. By using them, you enhance efficiency and maintain high-quality standards. These tools play a vital role in their common applications across industries.

Common Applications in Manufacturing

Precision Cutting in Paper and Film Production

Pneumatic blade holders excel in industries where precision is critical. In paper and film production, you can rely on these tools to achieve clean and accurate cuts. Whether you are working with thin films or thick paper rolls, pneumatic blade holders ensure consistent results. Their ability to adjust pressure and blade positioning allows you to handle delicate materials without causing damage. This makes them ideal for producing high-quality products like packaging films, adhesive labels, and specialty papers.

You can also use pneumatic blade holders to streamline your production process. By automating cutting tasks, they reduce manual effort and improve efficiency. This not only saves time but also minimizes waste, which is essential for cost-effective operations.

Metal and Plastic Cutting for Industrial Use

When it comes to cutting metals and plastics, pneumatic blade holders offer unmatched precision and durability. These tools are designed to handle tough materials, making them perfect for industrial applications. You can use them to cut sheets, strips, or custom shapes with ease. Their robust construction ensures they maintain performance even under heavy workloads.

Pneumatic blade holders also enhance safety in your workplace. By automating cutting processes, they reduce the risk of accidents associated with manual cutting tools.

Applications in Packaging and Converting Industries

Slitting and Trimming in Flexible Packaging

Pneumatic blade holders play a vital role in flexible packaging processes. You can use them to achieve precise slitting and trimming of materials like plastic films, laminates, and foils. These tools ensure clean edges, which is essential for creating high-quality packaging products. Their ability to adjust blade pressure and positioning allows you to handle various material thicknesses with ease. This adaptability makes them suitable for industries producing food pouches, shrink wraps, and other flexible packaging solutions.

By automating slitting and trimming tasks, you can significantly improve production speed. This reduces manual labor and minimizes errors, leading to consistent results. Additionally, pneumatic blade holders help reduce material waste, which lowers production costs and supports sustainability goals. Their reliability ensures they meet the demands of high-volume packaging operations, making them an indispensable tool in your workflow.

Label and Tape Production with Enhanced Accuracy

In label and tape production, precision is critical. Pneumatic blade holders provide the accuracy you need to cut materials into uniform shapes and sizes. Whether you are working with adhesive labels, masking tapes, or industrial tapes, these tools deliver consistent results. Their design allows you to make quick adjustments, ensuring seamless transitions between different production requirements.

You can rely on pneumatic blade holders to maintain high-quality standards in your products. They help eliminate uneven cuts and material defects, which enhances the overall appearance and functionality of labels and tapes.

Role in Textile, Nonwoven, and Food Industries

Cutting and Slitting Fabrics and Nonwoven Materials

Pneumatic blade holders are essential tools in textile and nonwoven material processing. You can use them to achieve precise cuts in fabrics, ensuring clean edges and consistent results. These tools handle a variety of materials, including woven textiles, nonwoven fabrics, and technical textiles. Their ability to adjust blade pressure and positioning allows you to work with delicate or thick materials without compromising quality.

In nonwoven material production, pneumatic blade holders help you create products like medical gowns, wipes, and filtration materials. Their precision ensures uniformity, which is critical for maintaining product performance.

Precision Cutting in Food Processing for Hygiene and Efficiency

In the food industry, pneumatic blade holders play a crucial role in maintaining hygiene and efficiency. You can rely on these tools to cut food products like dough, meat, or packaging materials with precision. Their design ensures clean cuts, reducing the risk of contamination. This makes them ideal for applications where hygiene standards are critical.

Pneumatic blade holders also enhance productivity in food processing. By automating cutting tasks, you can handle high volumes without compromising accuracy. These tools adapt to different materials, allowing you to switch between tasks seamlessly. Whether you are slicing packaging films or portioning food items, pneumatic blade holders ensure consistent results. Their reliability makes them a valuable asset in meeting the demands of modern food production.

Pneumatic blade holders provide you with unmatched precision and efficiency. Their ability to handle diverse materials makes them essential in manufacturing, packaging, textiles, and food processing. By investing in high-quality options, you can boost productivity and ensure consistent product quality. These tools help you meet industry demands while maintaining cost-effective operations.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

KA

KA

UR

UR

BN

BN