Proper maintenance of your pneumatic blade holder ensures efficiency, safety, and extended lifespan. Neglecting upkeep can lead to wear, misalignment, or reduced functionality. Regular care prevents costly repairs and downtime. By maintaining performance, you not only optimize cutting precision and operational reliability but also ensure that your equipment continues to maintain performance over time. A well-maintained blade holder safeguards your investment and enhances productivity in demanding applications.

Routine Maintenance to Maintain Performance

Cleaning the Blade Holder After Use

After each use, clean your pneumatic blade holder thoroughly. Dust, debris, and residue can accumulate on the holder, affecting its functionality. Use a soft brush or compressed air to remove loose particles. For stubborn grime, wipe the surface with a lint-free cloth dampened with a mild cleaning solution. Avoid using abrasive materials that could scratch or damage the holder. Regular cleaning ensures the blade holder operates smoothly and helps maintain performance over time.

Lubricating Blades and Moving Parts

Lubrication is essential for reducing friction and preventing wear on moving parts. Apply a high-quality lubricant to the blades and other mechanical components as recommended by the manufacturer. Focus on areas prone to frequent motion, such as pivot points and sliding mechanisms. Over-lubrication can attract dirt, so use only the necessary amount. Proper lubrication not only extends the lifespan of your blade holder but also ensures it continues to maintain performance during operation.

Inspecting for Wear, Damage, and Misalignment

Frequent inspections are critical for identifying potential issues before they escalate. Examine the blade holder for signs of wear, such as cracks, dents, or uneven surfaces. Check for misalignment, which can compromise cutting precision. Use a straight edge or alignment tool to verify that all components are properly positioned. Early detection of problems allows you to address them promptly, ensuring consistent performance and safety.

Replacing Worn or Damaged Components

Replace any worn or damaged parts immediately to prevent further complications. Components like blades, springs, and seals can degrade over time due to regular use. Consult the manufacturer’s guidelines to source compatible replacements. Installing new parts restores the blade holder’s efficiency and ensures it operates at peak performance. Proactive replacement of faulty components minimizes downtime and enhances the reliability of your equipment.

Proactive Tips to Extend Lifespan and Maintain Performance

Proper Storage of the Blade Holder

Store your pneumatic blade holder in a clean, dry environment to prevent damage from moisture or dust. Use a protective case or cover to shield it from accidental impacts. Avoid placing heavy objects on top of the holder, as this can deform its components. If possible, designate a specific storage area to keep the holder organized and easily accessible. Proper storage minimizes the risk of corrosion and ensures the equipment remains in optimal condition.

Avoiding Overloading or Overuse

Operate your blade holder within its recommended capacity to prevent unnecessary strain. Overloading the equipment can lead to premature wear or mechanical failure. Monitor usage patterns and allow the holder to cool down during extended operations. Avoid using the blade holder for tasks it wasn’t designed to handle. By respecting its limits, you reduce the likelihood of damage and extend its operational lifespan.

Scheduling Regular Professional Inspections

Schedule periodic inspections with a qualified technician to identify hidden issues. Professionals can detect wear, misalignment, or other problems that may not be visible during routine checks. These inspections also ensure that all components function as intended. Keep a maintenance log to track inspection dates and findings. Regular professional assessments enhance reliability and prevent costly repairs.

Ensuring Air Supply Quality and Pressure

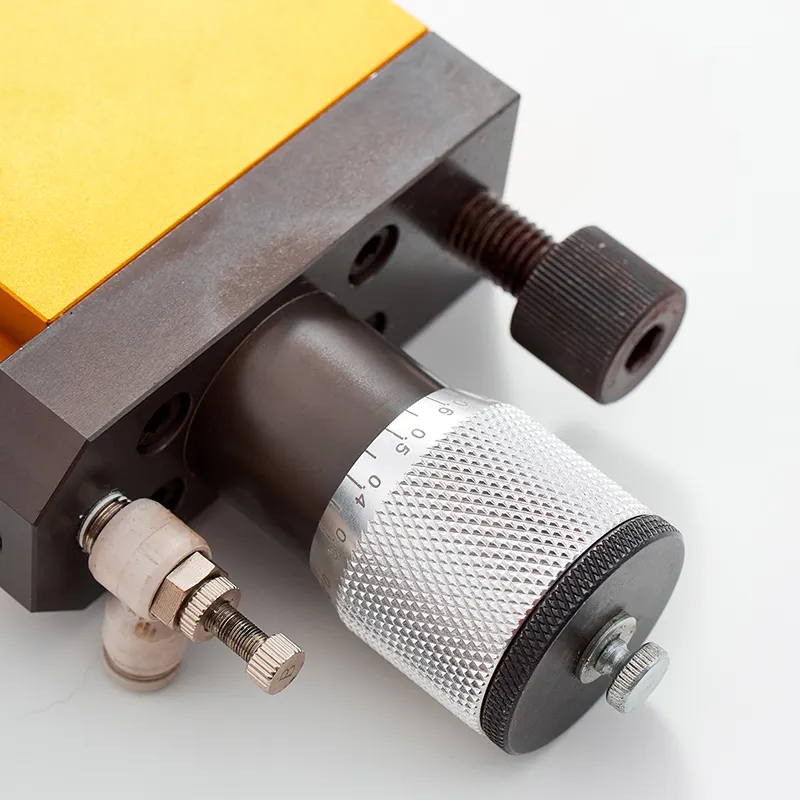

Maintain a clean and consistent air supply to optimize the performance of your pneumatic blade holder. Use filters to remove contaminants like dirt or moisture from the air system. Check the pressure regularly to ensure it matches the manufacturer’s specifications. Fluctuating or inadequate pressure can reduce efficiency and damage internal components. A high-quality air supply ensures smooth operation and prolongs the life of your equipment.

Maintaining your pneumatic blade holder ensures consistent performance and extends its lifespan. Routine maintenance, troubleshooting, and safety precautions protect your investment and improve efficiency. By following these practices, you reduce downtime and avoid costly repairs. Adopt these proactive measures today to keep your equipment operating safely and reliably for years to come.