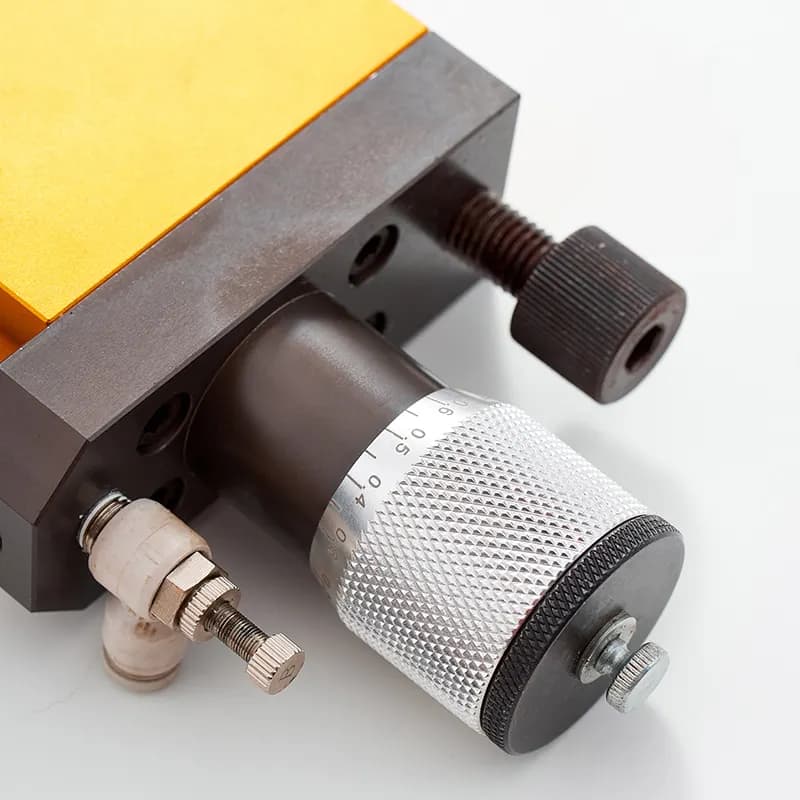

guide of pneumatic knife holder

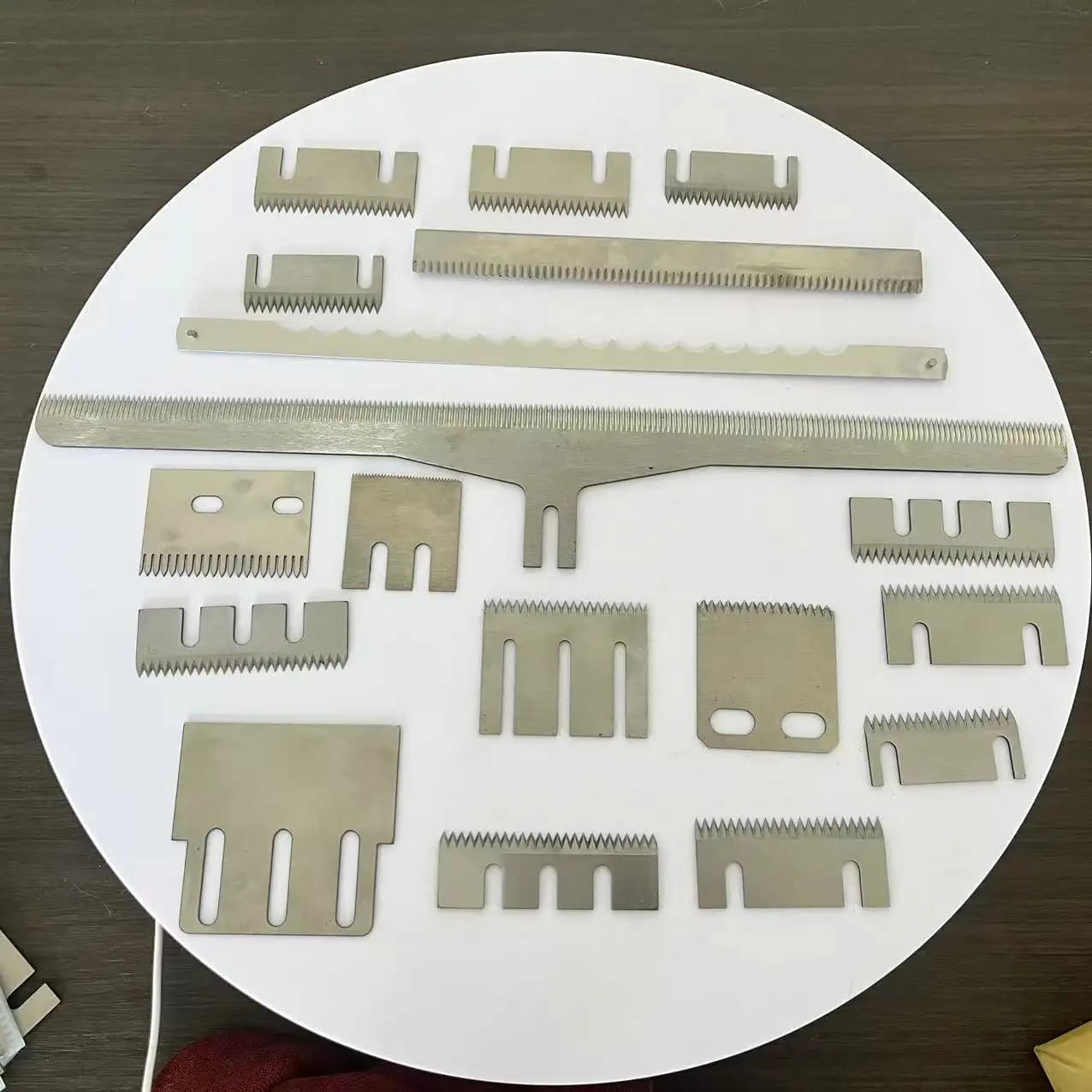

The guide of pneumatic knife holder is an innovative tool designed to enhance the efficiency and precision of cutting operations in industrial settings. Its main functions include the secure mounting and precise control of cutting knives used in various applications such as packaging, converting, and fabric processing. Technological features of the pneumatic knife holder guide include an air-powered mechanism for smooth and rapid adjustment, a robust build for durability, and an ergonomic design that promotes operator comfort. This guide ensures the knife is held firmly in place, allowing for more accurate cuts and increased productivity. Its applications span across industries where materials need to be cut with precision and speed, making it an indispensable tool for enhancing the overall performance of cutting processes.