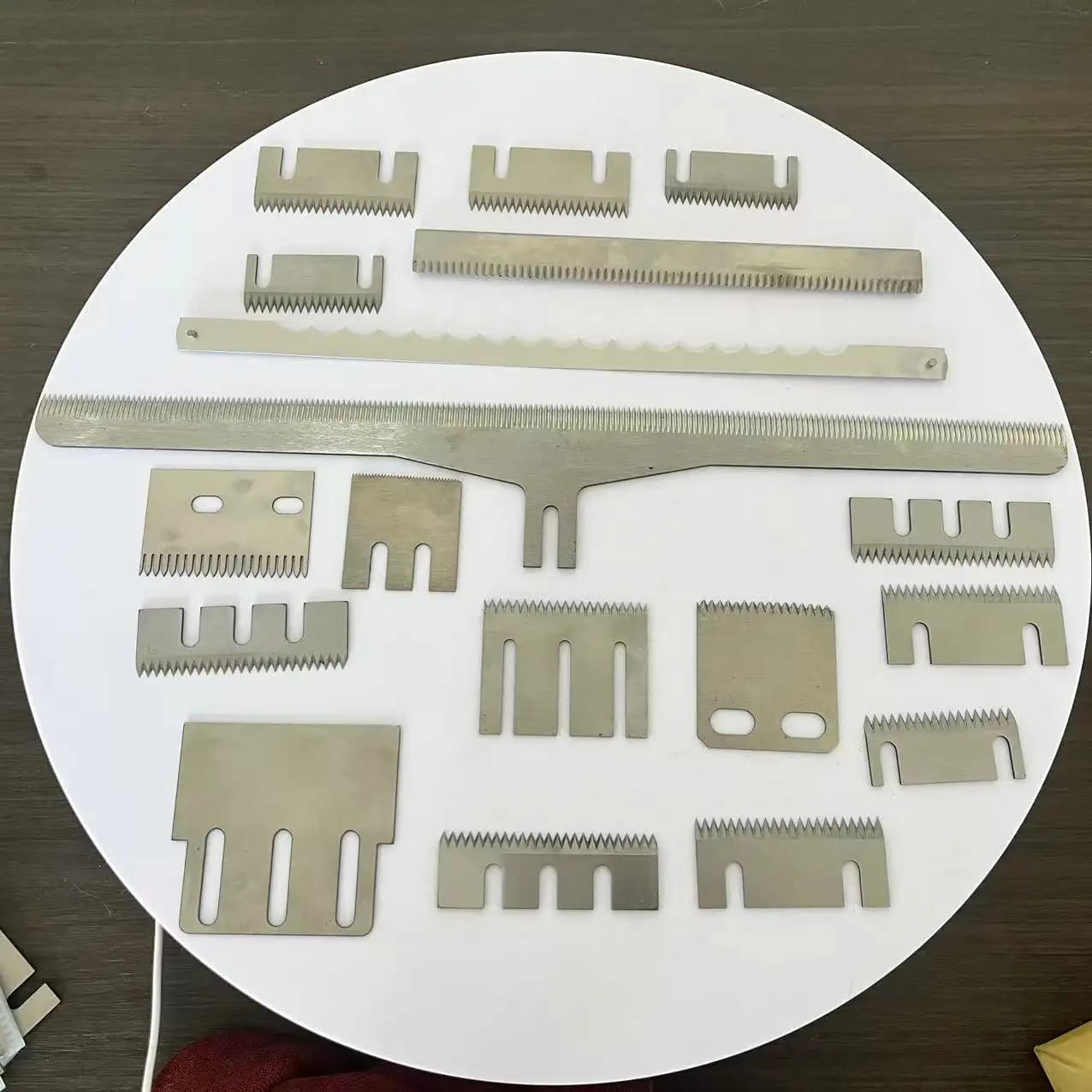

gear hobbing cutter

The gear hobbing cutter is a precision cutting tool used predominantly in the manufacturing of gears. Its main function is to cut the teeth of a gear blank, shaping it into a precise and functional gear. Technological features of this cutter include a hardened and ground steel construction for durability, variable pitch options for different gear specifications, and a unique cutting edge design that ensures efficient material removal and a superior finish. Gear hobbing cutters are versatile tools employed across various industries, from automotive to aerospace, where high-quality gears are crucial for the operation of machinery and equipment.