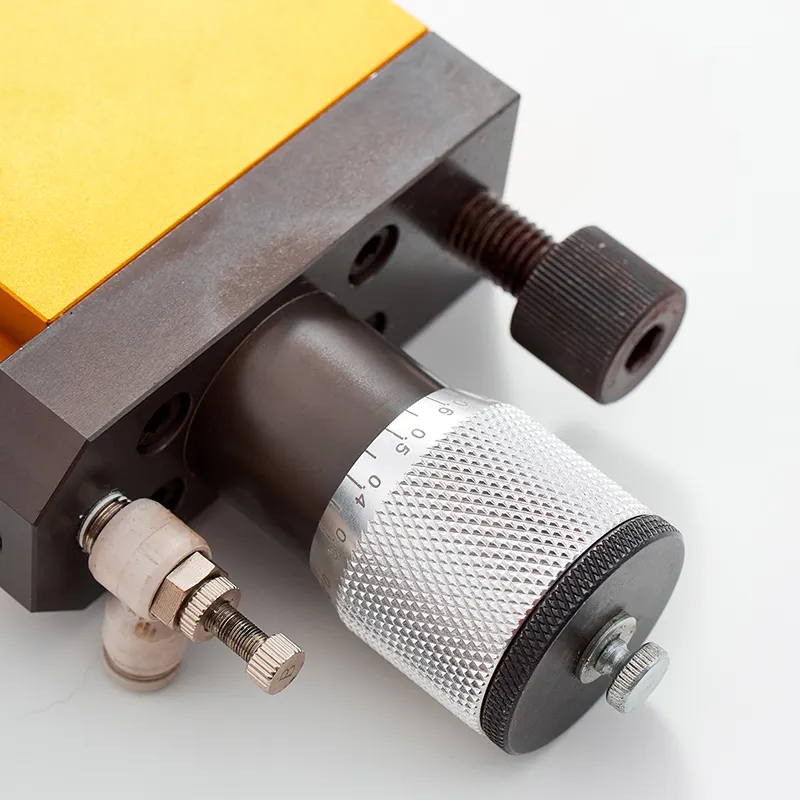

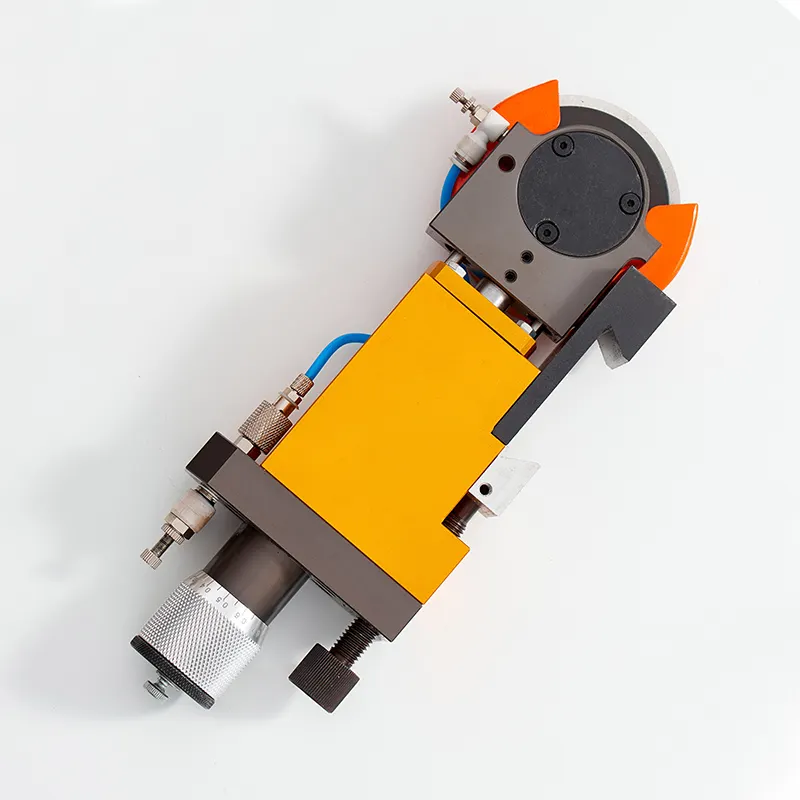

Proper maintenance of your pneumatic blade holder ensures efficiency, safety, and extended lifespan. Neglecting upkeep can lead to wear, misalignment, or reduced functionality. Regular care prevents costly repairs and downtime. By maintaining perform...

VIEW MORE

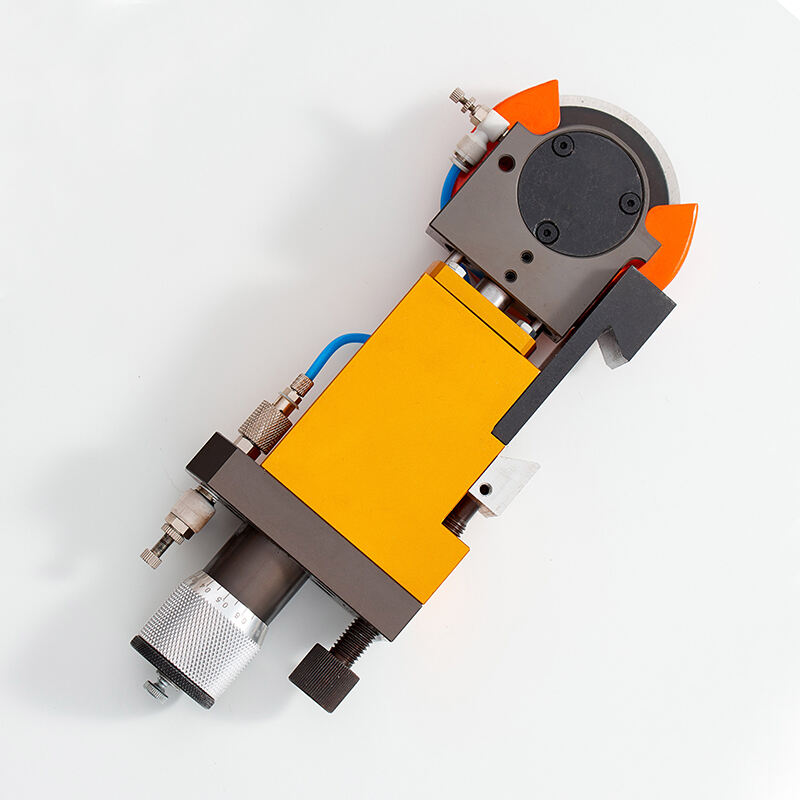

Pneumatic blade holders provide precise cutting solutions for various industries. You can rely on these tools for tasks like slitting, perforating, and trimming. Their design ensures consistent performance, even in demanding environments. By using th...

VIEW MORE

Pneumatic blade holders play a vital role in industrial cutting. You can rely on them for precision, efficiency, and safety. Their key features ensure consistent performance, making them indispensable for high-quality results. These tools simplify cu...

VIEW MORE

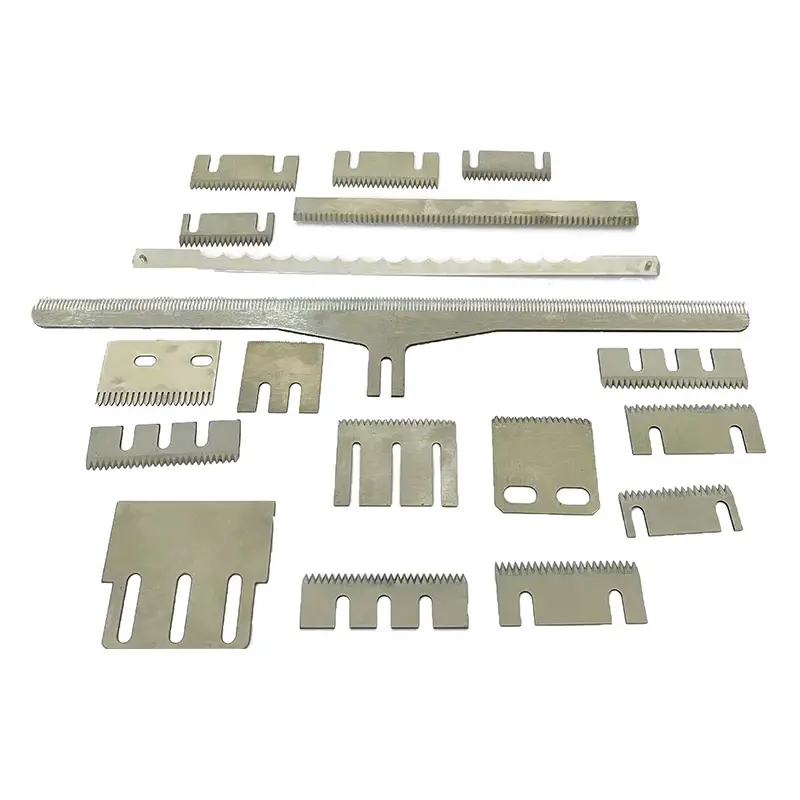

Blade wear results from factors like material hardness, abrasiveness, and poor maintenance. It disrupts crushing operations by lowering precision and increasing energy demands. Operators face frequent downtime and higher costs when wear remains unadd...

VIEW MORE

Cost-effectiveness measures how well crusher blades perform relative to their cost. You need to evaluate cost-effectiveness to ensure your operations remain efficient and profitable over time. Factors like blade durability, maintenance costs, and ret...

VIEW MORE

Choosing the right circular blade can make or break your project. The blade you select directly impacts how smoothly and efficiently you cut through materials. A high-quality blade ensures clean cuts, reduces wear on your tools, and keeps you safe du...

VIEW MORE

Keeping your circular blade in top condition takes effort, but it’s worth it. Regular maintenance helps you avoid costly replacements and ensures smooth, safe cuts every time. Proper usage prevents unnecessary stress on the blade, reducing the ...

VIEW MORE

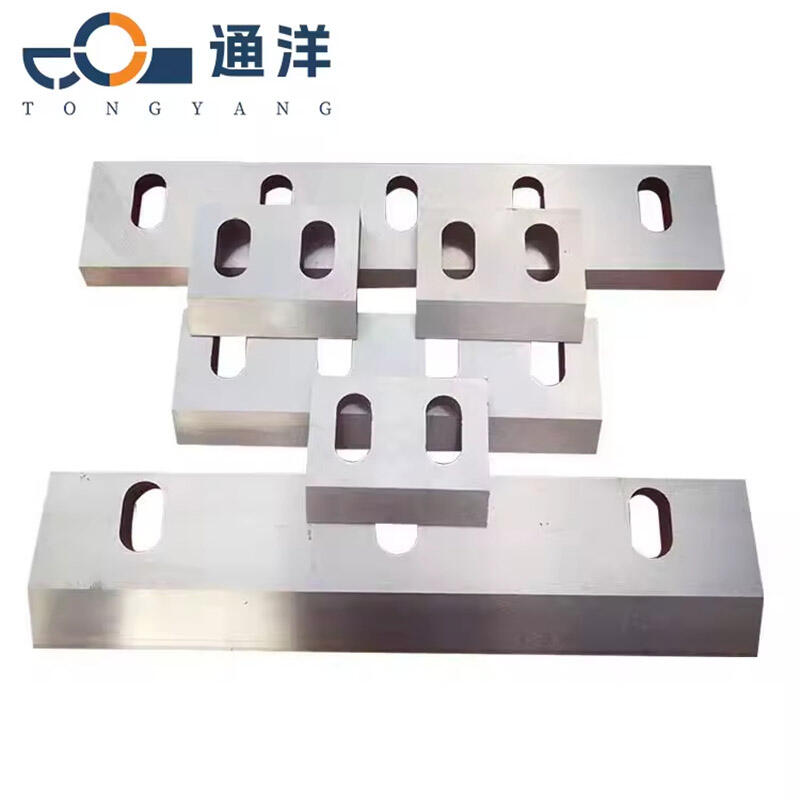

Efficient crusher blades rely on specific design features to deliver superior performance. High-quality materials enhance durability and ensure long-lasting use. Precise geometry improves cutting accuracy and reduces unnecessary strain during operati...

VIEW MORE

Crusher blades play a critical role in maintaining the efficiency of your machinery. You should replace them every 6 to 12 months, depending on how often you use the machine and the type of material it processes. Hard or abrasive materials wear down ...

VIEW MORE

Crusher blades often encounter problems that can disrupt their performance. Dullness reduces cutting efficiency and forces the machine to work harder. Chipping weakens the blade, making it prone to breakage. Rust compromises the blade’s durabil...

VIEW MORE

Introduction Be it woodworking or metal fabrication, all industries just cannot do away with ′round blades. Blade longevity is a huge driver of productivity and expenses in the business. Keeping a round blade flying economically makes sense, as...

VIEW MORE

Introduction Like how the material of a round blade is very much the deciding factor in its cutting tool world. Be it woodworking, metalworking, or even masonry cutting, the material makes all of a deep difference in edge hardness (how well it stays ...

VIEW MORE

Copyright © 2025 Ma 'anshan Tongyang Machinery Equipment Co., Ltd. All rights reserved. Privacy policy