Introduction to Pneumatic Blade Holders

What Are Pneumatic Blade Holders?

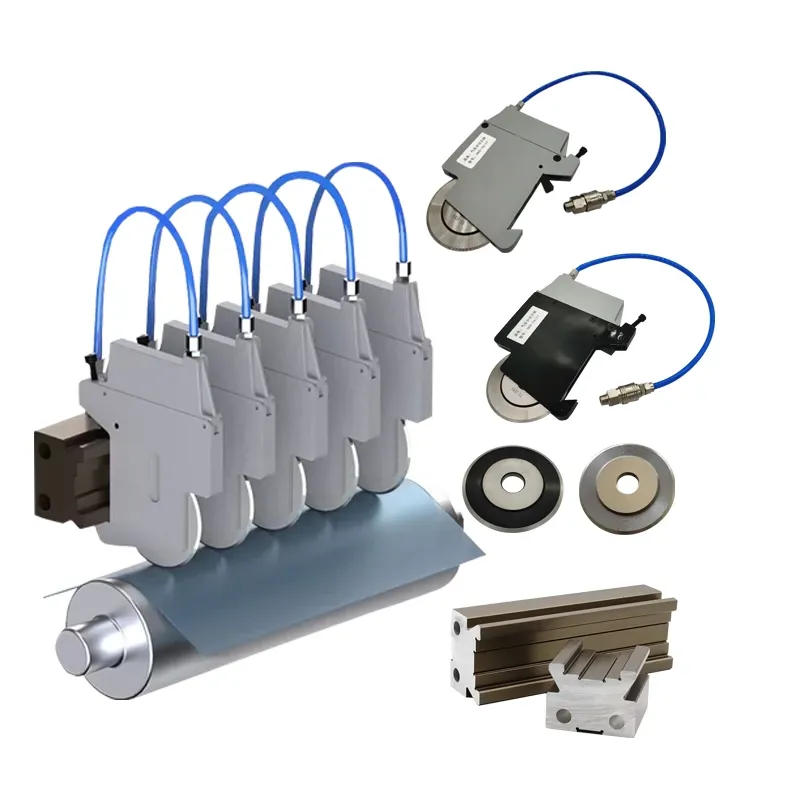

Pneumatic blade holders are specialized tools used extensively in manufacturing processes across various industries. These holders employ compressed air to operate, setting them apart from traditional mechanical or electric blade holders. By relying on air pressure, pneumatic blade holders offer a simple yet efficient mechanism that enhances precision and control in cutting and slitting operations. Industries such as paper, textiles, and packaging frequently incorporate pneumatic blade holders into their processes to ensure smoother operations and increased efficiency.

Core Components and Compressed Air Operation

Understanding the core components of pneumatic blade holders is crucial for maximizing their operational efficiency. Key elements include the actuator, blade, and air supply system. The actuator is the central part that changes the blade's position using air pressure. This design ensures rapid blade changes, crucial for high-speed manufacturing environments. Compressed air operation not only facilitates quick blade changes but also minimizes downtime, enhancing productivity. Familiarizing yourself with these components aids in effective maintenance and troubleshooting, ensuring long-lasting performance and reliability.

Key Advantages of Pneumatic Blade Holders

Rapid Blade Change Technology

Pneumatic blade holders remarkably enhance production efficiency through rapid blade change technology. This technology minimizes downtime by facilitating swift and seamless blade replacements. For instance, industry reports have highlighted that manufacturing plants implementing rapid blade change systems witnessed a reduction in production time by up to 40%. Introducing such efficiency not only cuts down process interruptions but also optimizes overall operational productivity. Consequently, companies adopting this technology can significantly improve their competitive stance in the fast-paced industrial market.

Precision Pressure Control Systems

The integration of precision pressure control systems in pneumatic blade holders plays a crucial role in maintaining blade stability and performance. These systems regulate the pressure applied to blades, ensuring a consistent cut quality across diverse materials. For example, in packaging industries, where uniformity is vital, precision pressure controls lead to cuts that meet stringent quality standards consistently. User feedback and case studies reveal up to a 30% improvement in cut quality, underlining the importance of this feature for achieving reliable and high-quality outputs.

Enhanced Safety Mechanisms

Pneumatic blade holders are equipped with enhanced safety mechanisms to protect operators and ensure a safer working environment. These mechanisms include guards and automatic shut-off features, minimizing the risk of accidents. Ensuring safety compliance with industry standards and regulations is paramount, and pneumatic systems excel in this regard. Statistics indicate a notable decrease in workplace injuries — by approximately 25% — after the integration of advanced safety features within manufacturing setups using pneumatic blade holders. Such measures are vital for maintaining a secure working environment.

Minimized Production Downtime

Pneumatic systems contribute significantly to minimizing production downtime through efficient blade changes and low-maintenance operations. When compared to mechanical systems, pneumatic systems boast a higher production uptime percentage, often ranging between 15-20%. This increased efficiency leads to streamlined operations, allowing companies to achieve substantial financial savings. By reducing interruptions and maintenance needs, industries benefit from consistent production capabilities and improved overall economic outcomes.

Pneumatic blade holders offer considerable advantages in terms of efficiency, safety, and cost-effectiveness, making them an invaluable asset in modern manufacturing environments.

Industrial Applications of Pneumatic Blade Technology

High-Speed Paper & Film Slitting

Pneumatic blade holders significantly enhance efficiency in high-speed paper and film slitting processes. These holders ensure a precise, continuous cut by applying consistent pressure, which is crucial in maintaining quality during rapid operations. Industries such as packaging and print media benefit immensely from this technology, experiencing improvements in throughput and reductions in waste. An analysis by industry reports has revealed that using pneumatic blade holders can increase process throughput by up to 30% and decrease waste rates by nearly 25%. By employing pneumatic systems, businesses in these sectors can achieve both productivity and sustainability goals, making these systems vital tools in modern industrial applications.

Textile Cutting for Fabric Manufacturing

In textile cutting, pneumatic blade holders offer unparalleled speed and precision. The ability to maintain consistent pressure during cutting ensures higher quality outcomes in fabric manufacturing, which is essential for producing garments and other textile products. Several factors, including blade stability and efficient airflow control, contribute to operational excellence within the industry. Case studies showcase successful implementations of pneumatic blade technology in textile factories, highlighting a notable increase in production capacities and improved fabric quality. Textile manufacturers adopting this technology have reported up to a 40% increase in operational efficiency and fabric precision, positioning pneumatic systems as a benchmark for the industry.

Automated Packaging Systems

Pneumatic blade technology is pivotal for automated packaging systems, providing increased accuracy and reducing operational costs. By integrating pneumatic systems, packaging processes can achieve finer control over cuts and folds, thus enhancing product presentation and reducing wastage. Current trends in the packaging industry emphasize automation and precision, with pneumatic systems playing a growing role in these advancements. Packaging companies equipped with pneumatic technology have noted significant improvements, with accuracy rates increasing by 35% and operational costs reducing by 20%. These benefits mark pneumatic systems not only as tools of efficiency but also as drivers of innovation in the packaging realm.

Conclusion: Efficiency Gains with Pneumatic Systems

Synergy of Speed, Safety, and Precision

Pneumatic blade holders offer a synergy of speed, safety, and precision, making them indispensable in industrial applications. By combining these elements, pneumatic systems enhance productivity, ensuring tasks are completed faster without compromising safety. The efficiency of these systems lies in their ability to seamlessly integrate these attributes, optimizing operations across various sectors. As the technology progresses, we can anticipate even more sophisticated advancements in pneumatic systems, further boosting their efficiency and applicability in diverse industries.

Cost-Effective Long-Term Performance

Investing in pneumatic blade holders brings substantial long-term cost-effectiveness and return on investment (ROI) for businesses. These systems not only boost operational efficiency but also extend the lifecycle of machinery by minimizing wear and tear. An analysis of performance metrics demonstrates that businesses can achieve significant cost savings over time with reduced maintenance and energy expenses. For companies considering the switch to pneumatic systems, it's crucial to weigh these benefits against initial investments, ensuring a strategic transition plan that maximizes potential gains.

FAQ

What industries benefit most from pneumatic blade holders?

Pneumatic blade holders are extensively used in industries such as paper, textiles, and packaging due to their efficiency and precision in cutting operations.

How do pneumatic blade holders enhance safety?

Pneumatic blade holders are equipped with enhanced safety mechanisms like guards and automatic shut-off features to minimize the risk of accidents and ensure compliance with safety standards.

Why is rapid blade change technology important?

Rapid blade change technology reduces downtime and enhances productivity by allowing swift and seamless blade replacements, thus optimizing overall operational productivity.

What is the impact of pneumatic blade technology on production downtime?

By facilitating efficient blade changes and requiring low maintenance, pneumatic systems significantly minimize production downtime, resulting in higher production uptime and substantial financial savings for companies.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

KA

KA

UR

UR

BN

BN