Benefits of Regular Round Blade Maintenance

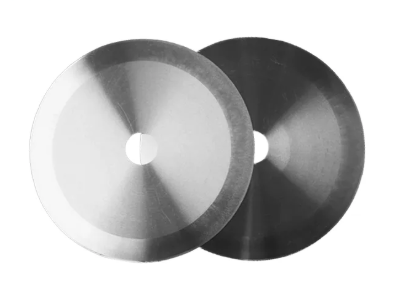

Extended Lifespan Through Preventative Care

Regular maintenance is key to prolonging the lifespan of round blades, as evidenced by the recommendations of the Machinery and Equipment Manufacturers Association. By incorporating preventative care practices, one can often double the operational life of blades in comparison to those neglected. This practice involves establishing a consistent maintenance schedule to minimize unexpected failures. Effective care not only defers costly replacements but also prevents production delays, illustrating that a proactive approach to maintenance is indeed cost-effective.

Improved Cutting Precision and Efficiency

The advantages of routine maintenance are profoundly reflected in a blade's cutting precision and efficiency. Studies indicate that sharpening and maintaining blades regularly can amplify cutting performance by up to 30%. With maintained blades, operations run smoothly, offering a significant improvement in material finishes while reducing waste. This not only ensures a superior product quality but also emphasizes the advantage of consistent blade maintenance for optimal efficiency. Overall, maintaining your blades results in more precise, effective cuts and a marked reduction in material waste.

Enhanced Safety During Operation

Well-maintained blades contribute significantly to workplace safety by reducing operational hazards. The Occupational Safety and Health Administration (OSHA) emphasizes that regular equipment maintenance is fundamental for safety compliance. With consistent checks and maintenance, issues like blade breakage or malfunctioning equipment, which could pose serious risks during operation, are effectively curtailed. Thus, regular maintenance not only boosts productivity but also plays a crucial role in ensuring a safe working environment for all.

Cleaning and Sharpening Techniques for Round Blades

Removing Resin and Debris Build-Up

Removing resin and debris build-up from round blades is crucial for maintaining their performance. Accumulation of these materials, especially high-resin ones, can significantly affect the cutting quality and even lead to equipment malfunction. To effectively deal with this issue, I recommend using a suitable solvent that can efficiently dissolve and eliminate these residues. Doing so not only improves the blade's operational efficiency but also helps extend its overall lifespan by keeping it free from harmful deposits.

Step-by-Step Sharpening Process

The sharpening process of round blades requires a systematic and careful approach to ensure effectiveness and precision. It starts with assessing the blade's edge for any dull spots or damage. This initial evaluation is crucial for determining the appropriate level of sharpening needed. Utilizing a sharpening guide or fixture during this process can help maintain the correct angle, ensuring consistent and precise results. By following this structured approach, I can enhance the blade's performance and prolong its usability, allowing for optimal cutting efficiency.

Signs Your Blade Needs Professional Sharpening

Recognizing when a blade needs professional sharpening is essential for maintaining cutting performance. Some key indicators include noticeable dullness, excessive heat generation during use, and irregular cutting patterns. If regular maintenance efforts fail to restore the blade's sharpness or performance, it is advisable to seek professional sharpening services. According to industry experts, professional intervention can restore the blade to its optimal condition, ensuring that it performs efficiently and safely throughout its lifespan.

Lubrication and Blade Protection Strategies

Choosing the Right Lubricant for Round Blades

Selecting the appropriate lubricant is crucial for extending the life and enhancing the performance of round blades. Different materials and cutting conditions necessitate specific types of lubricants to achieve optimal results. For example, certain high-performance cutting operations may require lubricants with higher viscosity. To make informed decisions, it's advisable to consult manufacturer recommendations, as they can provide guidance tailored to the specific needs of your equipment. By doing so, you're ensuring the longevity and efficiency of your cutting tool.

Preventing Rust and Corrosion

Applying a protective coating or lubricant can effectively prevent rust and corrosion, especially in humid environments that are known to accelerate these issues. Regular application creates a barrier protecting the metal surface from moisture and other corrosive elements. Complementing this approach with routine inspections helps identify early signs of corrosion, allowing timely interventions to prevent damage. Keeping proactive in maintenance not only safeguards the blade's integrity but also enhances performance longevity.

Avoiding Overheating During Use

Strategic lubrication combined with appropriate tool speed are key factors in mitigating overheating in round blades—a critical aspect of maintaining blade integrity and performance. By maintaining a balanced approach to lubrication and adjusting operational speed based on material thickness and density, overheating incidents can be effectively minimized. Additionally, monitoring operating conditions closely can serve as an early warning system to prevent potential damage, ultimately ensuring the blade remains in optimal working condition for prolonged periods.

Proper Storage Practices for Round Blades

Climate-Controlled Storage Solutions

Maintaining blades in climate-controlled environments is essential for preventing moisture and extreme temperatures from causing damage. When round blades are exposed to fluctuating temperatures and humidity, they can suffer from rust and corrosion, reducing their effectiveness and lifespan. By implementing temperature and humidity controls, we can prolong the life and functionality of round blades. These measures ensure that the blades stay sharp and ready for use whenever needed, avoiding unnecessary wear and financial costs associated with frequent replacements.

Using Protective Covers and Racks

Protective covers are vital for shielding blades from dust and physical damage during storage. Dust and accidental impact can lead to surface abrasions and dulling, which compromise the blade's performance. By using designated racks, we can keep blades organized and easily accessible, reducing the risk of damage from careless handling. Investing in high-quality storage solutions, such as customized racks and durable covers, can significantly prevent unnecessary wear and tear, ensuring that the blades maintain their sharpness and efficiency over time.

Avoiding Cross-Contamination with Other Tools

Proper organization is crucial to prevent cross-contamination between different tools, which can lead to unintended dulling or damage to round blades. When blades come into contact with other tools, the chances of scratching or chipping increase, affecting their cutting accuracy. Educating staff on the importance of keeping blades stored separately from other equipment is essential to safeguarding their integrity. By implementing strict storage protocols and training programs, we can ensure that blades remain in optimal condition, ready to deliver precise cuts without compromise.

Repair vs. Replacement: Making the Right Choice

Assessing Minor Damage (Chips, Dull Edges)

To determine whether a round blade requires repair or replacement, assessing minor damages like chips and dull edges is crucial. Regular evaluations can uncover signs of wear that might be addressed through sharpening, thus negating the need for a complete replacement. Systematic reviews of blade conditions not only prevent mishandling but also offer substantial cost savings by reducing unnecessary purchases. A proactive approach to inspection ensures blades maintain peak performance, providing clarity on when maintenance suffices.

When Structural Integrity is Compromised

When assessing round blades, significant structural damage necessitates serious consideration for replacement. Indications such as cracks or deformities reflect a compromised blade, which can pose safety risks if unresolved. Understanding these symptoms can be pivotal in avoiding potential accidents related to blade malfunction. By focusing on structural integrity, users can ascertain when it is imperative to substitute a blade for its—and their—safety.

Cost-Effective Sharpening vs. New Blade Investment

Deciding between sharpening existing blades or investing in new ones hinges on a cost-benefit analysis. Often, routine sharpening is more economical as it extends the blade's life and maintains functionality without incurring the high costs associated with frequent replacements. Regular maintenance translates to cumulative savings over time, promoting efficiency and cost-effectiveness. Evaluating these factors provides businesses with the information needed to make financially prudent decisions.

FAQ

Why is regular blade maintenance important?

Regular maintenance extends the lifespan of round blades, improves cutting precision, enhances safety during operations, and minimizes unexpected failures.

How do I remove resin and debris buildup from blades?

Use a suitable solvent to dissolve and eliminate the residues, which improves operational efficiency and helps extend overall lifespan.

What are the signs a blade needs professional sharpening?

Noticeable dullness, excessive heat generation during use, and irregular cutting patterns indicate the need for professional sharpening.

How does proper storage prevent blade damage?

Climate-controlled environments, protective covers, and proper organization prevent rust, physical damage, and cross-contamination with other tools.

When should I replace a round blade?

Consider replacement if significant structural damage like cracks or deformities is observed, as it poses safety risks.