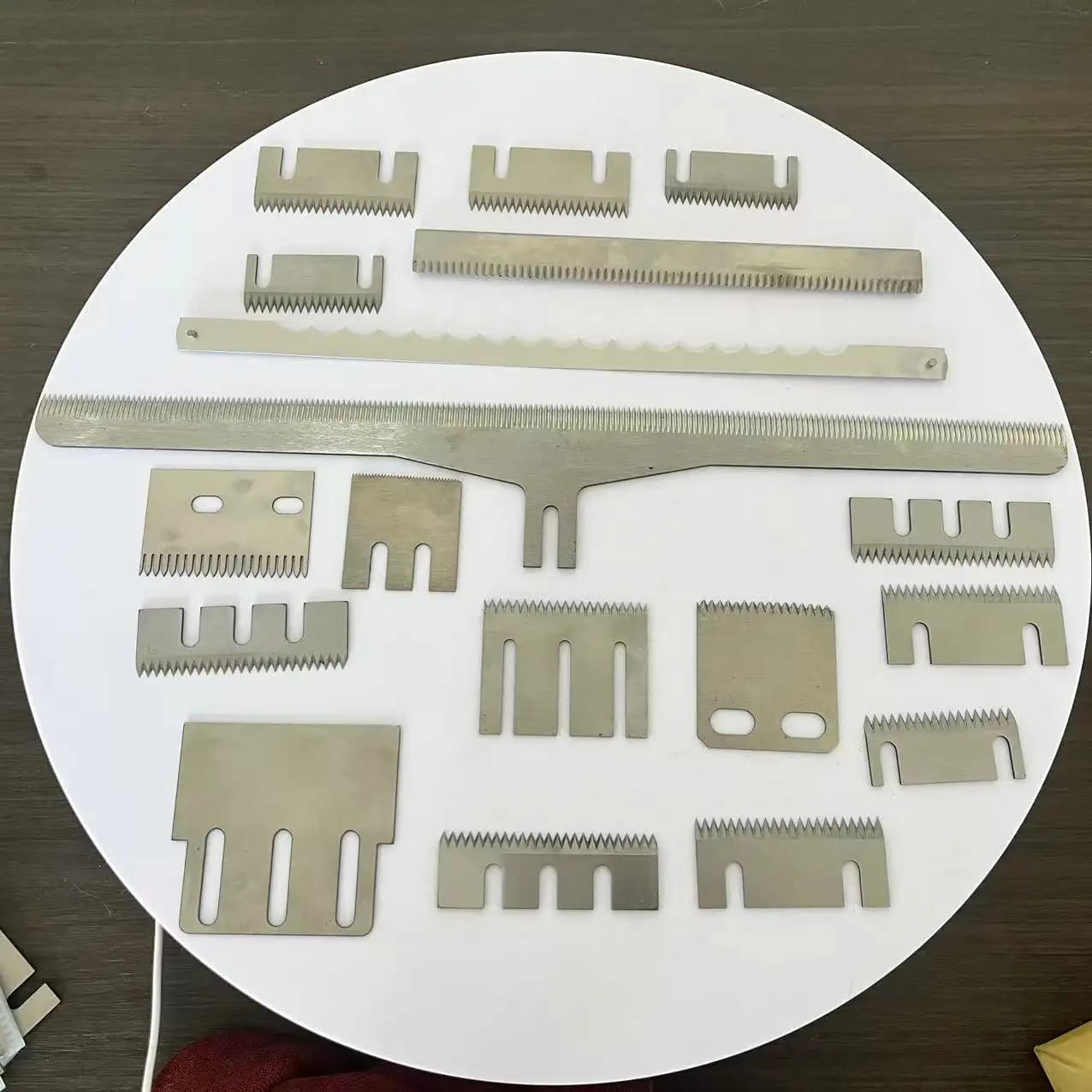

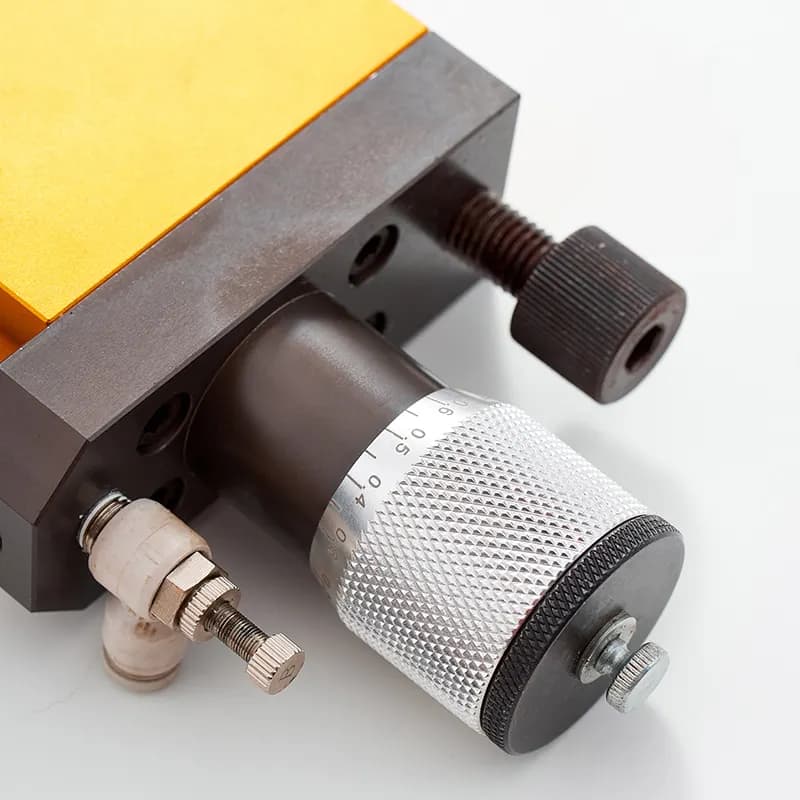

pneumatic knife holders blades

Pneumatic knife holders blades are precision tools engineered for efficiency and durability in industrial cutting applications. These advanced cutting systems are powered by compressed air, providing consistent and powerful cutting force. Main functions include precise material trimming, slitting, and裁cutting across various materials such as paper, plastic, and metal. Technological features include a robust design that minimizes downtime, an ergonomic handle for operator comfort, and an interchangeable blade system that allows for quick and easy blade replacement. These pneumatic knife holders are widely used in manufacturing plants, packaging facilities, and printing industries where precision and speed are paramount.